To find good silicone linear lights at reasonable prices, you need to know how things are made in China. This complete guide shows price strategies, the best products, and buying tips that will help engineering workers and sourcing managers make smart choices. Silicone linear lights from good Chinese companies cost between $8 and $50 per meter, based on the specs, certifications, and customization needs. Knowing about these price changes gives buyers the power to get the best deals while still keeping high standards.

Why Silicone Linear Lighting Solutions Dominate Commercial Projects?

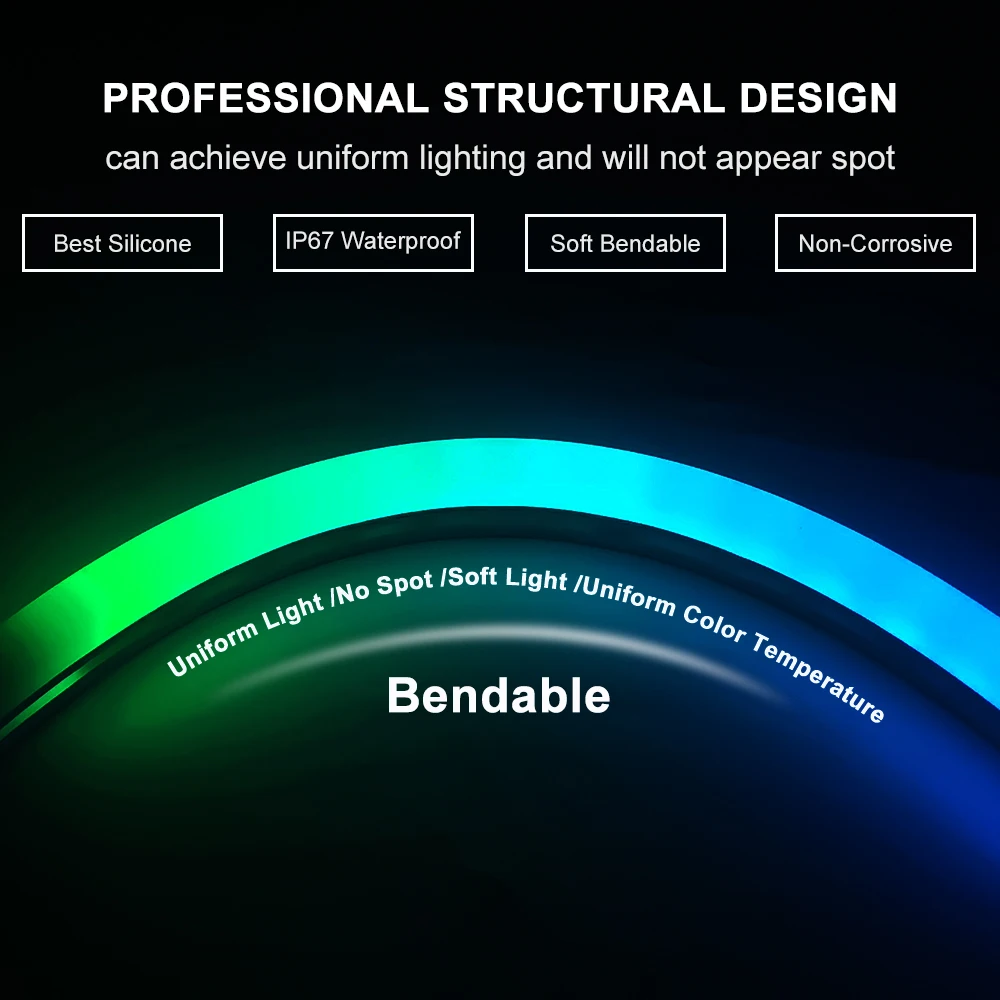

Silicone linear LED lights have become very popular in the business lighting market around the world because they are very flexible and last a long time. Compared to standard metal shapes, silicone insulation is better at keeping out wetness, dust, and changes in temperature. Because it is so strong, waterproof silicone linear lighting is perfect for tough places like swimming pools, outdoor walls, and factories. Facility managers are choosing silicone LED neon flex options more and more because they are less likely to break than glass neon, while still looking good. Because silicone is flexible, it can be installed without any gaps around corners and bends.

This makes installation easier and cheaper labor. Engineers like that silicone linear lights lamps work the same in temperatures ranging from -40°C to 80°C, so they can be used reliably in a variety of regions. The material's natural resistance to UV light keeps the color from fading and breaking down, so the product will always look the same. Because they last longer, silicone linear lighting is a good investment for businesses because it saves money on maintenance costs and replacement rounds.

Essential Selection Criteria for Professional Procurement

A methodical technique focused on performance measures, approval compliance, and production skills is needed to evaluate silicone linear light providers. The first thing that is looked at to judge the quality of a silicone substance is its Shore A hardness grade. For best flexibility and sturdiness, this should be between 60 and 80. Platinum-catalyzed silicone, which is used by high-end makers, is clearer and lasts longer than peroxide-cured silicone. The quality of the LED chips has a big effect on how well they work and how much they cost.

Samsung, Osram, and Epistar chips cost more, but they keep their brightness levels and colors more stable. Chinese companies that make silicone LED rope lights with brand-name chips usually charge 15–20% more than generic options, but this extra cost guarantees reliable performance and warranty protection. Different markets have different certification needs. For example, in Europe, products must have a CE mark, and in North America, they must have a UL rating. Qualification by the DLC gives energy refund programs more authority.

People who work in procurement should use formal databases to make sure that certifications are real, since fake papers can put companies at risk of being sued. When you do a manufacturing capacity review, you look at things like the amount of work that can be done, the quality control systems, and how consistent the lead times are. Suppliers you can trust keep their ISO 9001 certification up to date and use statistical process control to make sure that each batch is the same. The amount of work that can be done each month should match the schedule for the project. For well-known makers, this amount is usually between 10,000 and 100,000 meters.

Premium Waterproof Silicone Linear Lighting Systems

High-end waterproof silicone linear light systems have security grades of IP67 and better heat control. For better heat absorption, these goods use 2835 or 3030 LED chips that are placed on double-layer PCBs that are 2oz thick copper. The best models have phosphor coatings that get CRI values of 90 or higher while still having great light efficiency above 120lm/W. Premium systems usually cost between $25 and $45 per meter, which is a reflection of their complex engineering and high-quality parts.

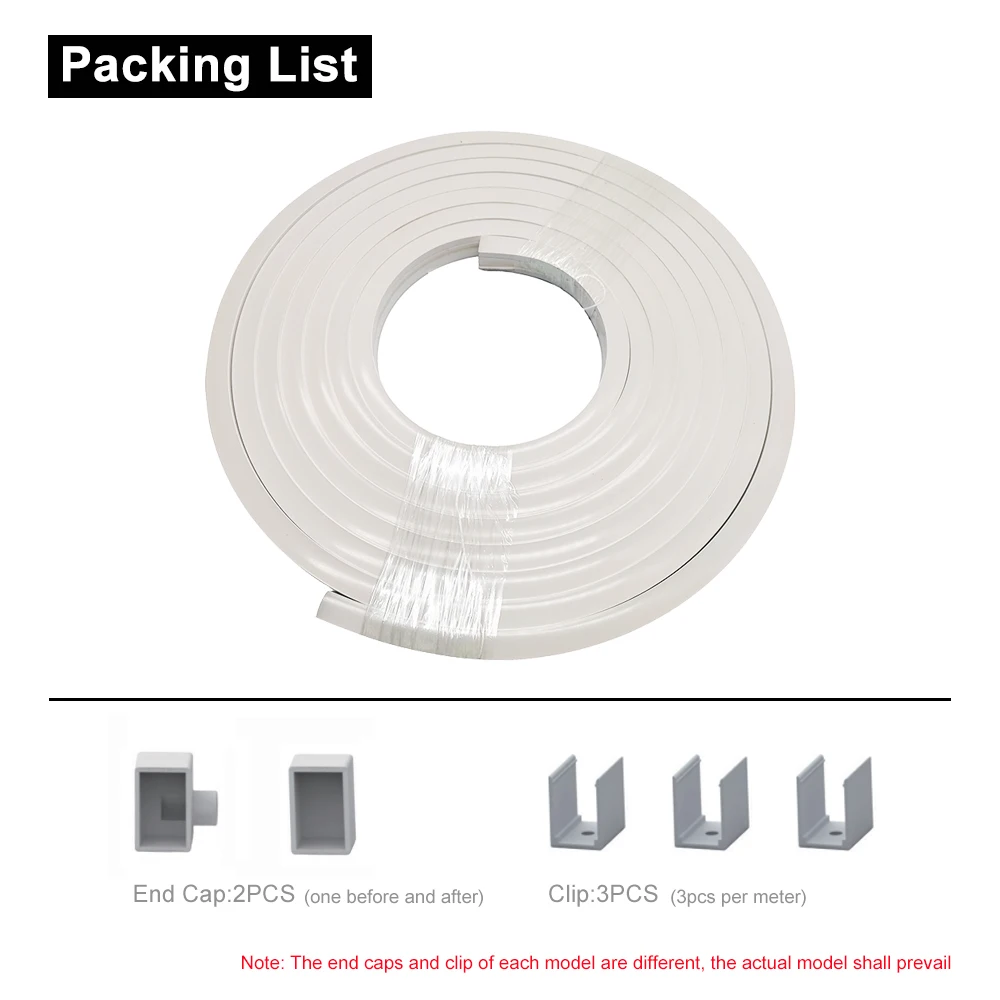

Advanced choices let you mix RGB and W colors and control each zone separately, which makes it possible to use dynamic lighting effects in building settings. The UV protectors and anti-static chemicals in the rubber case keep the optics clear and stop dust from building up. These systems come with installation tools like metal fixing channels with built-in heat sinks and rubber linear light diffusers that stop LEDs from shining in one spot. High-quality end caps made for professionals close well and make upkeep easy.

Compression joints and pressure release devices in cable access systems keep the IP grade valid. Dimming works with a lot of different standards, like 0-10V, DALI, and wireless systems. Modern models can dim from 0.1% to 100% smoothly and without flicker, which meets strict standards for business lights. Temperature adjustment techniques change the output automatically to keep the color consistent even when the environment changes.

Mid-Range Flexible Silicone Strip Lights

Flexible silicone strip lights in the middle range are usually priced between $12 and $25 per meter and offer a good mix of performance and price. These items use 2835 LED chips that have a performance level of 90+ CRI and an IP65 grade, which means they are safe for most industrial uses. The rubber housing stays flexible down to -20°C and protects against UV light well enough for indoor and protected outdoor installs. Standard setups include running on 24V and having power levels between 10W and 18W per meter.

There are color temperature choices from 2700K to 6500K, and tight binning limits make sure that the colors stay the same across big setups. Cutting happens about every 50 to 100 mm, which gives installers more options without putting electrical safety at risk. High-quality mid-range goods have strengthened circuit lines made of 22AWG wire that is made of tinned copper. This standard makes sure that the power stays stable over long distances of up to 10 meters without dropping too much. The adhesive backing is made of 3M VHB tape, which keeps its sticking power even when the temperature and humidity change.

Standard 0-10V and PWM methods are supported for dimming, and some types can connect to a smart home via WiFi or Zigbee for smart home integration. Accessories for installation include fixing clips, corner connectors, and power input parts that make complicated plans easier to understand. The warranty usually lasts between 3 and 5 years, as long as the product is installed and used correctly and within the limits set by the manufacturer.

Budget-Friendly Silicone LED Tube Lights

Starting at $8 to $15 per meter, entry-level silicone LED tube lights are a cheap way to light up simple spaces. With IP44 grades for safety and normal efficiency levels of around 100lm/W, these goods do the basics. Even if the specs aren't very high, good makers make sure that they meet basic safety standards and that the lights work well for everyday use. Standard setups use 2835 LED chips with color temperatures of 3000K or 4000K and CRI values of 80 or more.

The rubber housing protects against UV light and is flexible enough to be installed in simple bent shapes. There are 12V and 24V operating energy choices, and the power density ranges from 6W to 12W per meter. Single-layer PCB with standard copper thickness and basic heat control are some of the construction features. Even though it might not be able to get rid of heat as well as more expensive choices, if you place it correctly and make sure there is enough air flow, it should work well for a long time.

Cutting happens about every 100 mm, and there are solder pad links that allow for customization in the field. There are some markets where these low-cost choices are good, like temporary installs, show lights, and uses where replacements aren't too often. Good sellers give detailed spec sheets and warranties that are reasonable, usually for two to three years under normal conditions. To get the desired results from an installation, care must be taken with both temperature control and electricity loading.

Global Market Dynamics and Regional Considerations

Design and approval rules for silicone linear lights around the world are affected by regional tastes in a big way. In North America, projects put a lot of weight on UL and ETL approvals and strictly follow NEC construction rules. Most voltage standards need 120V to work with the TRIAC lowering systems that are common in business buildings. When it comes to European markets, following the rules for CE marking and RoHS materials is more important than 230V operating and DALI lighting procedures. Rules about saving energy make people want high-efficiency goods that put out more than 120lm/W.

Because of their harsh environment, Nordic countries need higher low-temperature performance standards. For jobs in the Middle East, it's common to ask for better UV protection and the ability to work at high temperatures to handle the hot conditions. Corrosion protection is very important for sites near the coast, where salt spray makes things difficult. For dining and home use, color temperature tastes lean toward warmer ranges (2700K–3000K).

Southeast Asian markets are showing a growing desire for smart lights that can be controlled by a mobile app. Because of warm regions, humidity resistance needs are higher than normal. Local licensing rules are very different, so you have to be very careful when choosing a supplier to make sure you follow the rules. SAA approval and C-Tick electromagnetic compatibility guidelines must be met by all Australian projects. Focusing on energy efficiency is in line with government efforts to protect the environment, which increases the need for high-quality efficiency goods. Installations in remote areas need to be more reliable and have longer guarantee coverage.

Professional Purchasing Recommendations and Implementation Strategy

To successfully purchase a silicone linear light housing, you need to follow an organized process that balances cost concerns with performance needs. As part of the initial project review, the surroundings, the difficulty of installation, and the ease of entry for upkeep should all be listed. These things have a direct effect on choosing the right product and how much it costs in the long run. When evaluating a supplier, you should look at their production capabilities, make sure their quality system works, and check their financial security.

Site trips are a great way to learn about how things are made and how quality control works. Companies that have been around for a while usually have special silicone molding lines with automatic quality tracking systems. Accelerated age tests, temperature cycles, and optical proof should all be part of the sample review process. Testing done by a separate lab verifies what the maker says and gives objective performance information. Checking the color uniformity of different production batches ensures that the amounts of differences are okay for big projects.

When negotiating a contract, you should talk about how to protect intellectual property, quality standards, delivery dates, and the terms of the guarantee. The way you get paid should be in line with the project's goals and include quality holdback rules. Force majeure terms protect against problems in the supply chain while keeping service promises. Lighting designers, electricity workers, and building management teams all need to work together to plan installations. The right way to handle heat and electricity keeps things from breaking down too soon and ensures the guarantee is followed. Photometric records, installation guides, and upkeep methods are all examples of documents that must be kept.

Industry Trends and Market Outlook

The silicone linear lighting market continues evolving toward smart integration and enhanced sustainability. Manufacturers increasingly incorporate IoT connectivity, enabling remote monitoring and predictive maintenance capabilities. Advanced sensor integration provides occupancy detection and daylight harvesting functionality that optimizes energy consumption. These technological advances position silicone linear lighting as a cornerstone of intelligent building systems, driving continued market growth and innovation opportunities.

Conclusion

Navigating the Chinese silicone linear lights market requires understanding quality indicators, certification requirements, and supplier capabilities. Premium solutions justify higher costs through superior performance and reliability, while budget options serve specific application needs effectively. Regional market preferences influence product specifications and certification requirements significantly. Successful procurement depends on thorough supplier evaluation, clear specification definition, and structured contract negotiation. The evolving market continues advancing toward smart integration and enhanced sustainability, creating new opportunities for innovative applications. Professional buyers benefit from partnering with established manufacturers who demonstrate consistent quality, reliable delivery, and comprehensive technical support capabilities.

Frequently Asked Questions

What is the typical lifespan of quality silicone linear lights?

Premium silicone linear lights typically achieve 50,000+ hour lifespans when properly installed and operated within specified parameters. The silicone housing provides excellent protection against environmental factors that commonly cause premature LED degradation. Quality manufacturers provide L70 lumen maintenance data supporting these lifespan claims through accelerated testing protocols.

How do I verify the authenticity of international certifications?

Certification authenticity can be verified through official databases maintained by testing laboratories. UL certifications are searchable through the UL Product iQ database, while CE declarations require verification of notified body involvement. Request complete test reports rather than certificate copies, and verify testing laboratory accreditation through appropriate national authorities.

What factors most significantly impact pricing from Chinese manufacturers?

LED chip brand, certification requirements, and customization complexity represent the primary pricing variables. Premium chip brands increase costs 15-20% while international certifications add $2-5 per meter. Customization, including special color temperatures, dimming protocols, or mechanical modifications, typically requires minimum order quantities of 1,000-5,000 meters and increases unit costs 10-30%.

Partner with USKYLED for Premium Silicone Linear Lighting Solutions

USKYLED stands ready to support your next project with premium silicone linear light strip solutions engineered for demanding commercial applications. Our advanced manufacturing capabilities include custom OEM/ODM development, comprehensive certification compliance, and reliable bulk supply capacity. We understand the unique challenges facing sourcing managers and engineering professionals when selecting lighting suppliers.

Our technical team provides detailed specification support and application guidance to ensure optimal product selection. Quality assurance protocols include incoming material inspection, automated production testing, and final shipment verification. We maintain extensive certification portfolios, including UL, CE, RoHS, and DLC qualifications, to support global distribution requirements.

Connect with our experienced sales team to discuss your specific requirements and receive competitive pricing for your upcoming projects. We offer comprehensive support from initial concept through final delivery, ensuring smooth project execution and superior results. Ready to explore premium silicone linear lights manufacturer options? Contact us at sales@uskyled.com and discover how USKYLED delivers exceptional value for commercial lighting professionals worldwide.

References

1. International LED Professional Magazine. "Silicone Housing Technologies in Linear LED Applications." LED Professional Review, Issue 78, March 2023.

2. Strategies in Light Conference Proceedings. "Global Market Analysis: Linear LED Lighting Trends and Manufacturing." Strategies Unlimited Research, 2023.

3. Building Design + Construction Magazine. "Specification Guide: Flexible LED Linear Lighting Systems for Commercial Applications." BD+C Technical Report, September 2023.

4. Lighting Design + Application Journal. "Waterproof LED Linear Systems: Performance Testing and Application Guidelines." LDA Technical Analysis, Volume 53, Number 4, 2023.

5. International Association of Lighting Designers. "Best Practices for Linear LED Specification in Commercial Projects." IALD Technical Guidelines, Second Edition, 2023.

6. IEEE Industry Applications Society. "Thermal Management and Reliability Assessment of Silicone-Encapsulated LED Linear Arrays." IEEE Transactions on Industry Applications, Vol. 59, No. 3, May 2023.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)