Introducing Low-Voltage Tube Lights: Technology and Benefits

What Are Low-Voltage Tube Lights?

Low-voltage tube lights are a type of lighting fixture that operates at voltages lower than standard mains electricity. Typically, these lights run on 12V or 24V DC power, as opposed to the 120V or 240V AC used in most electrical systems. This lower voltage operation is achieved through the use of transformers or drivers that convert the main power supply to the required low voltage.

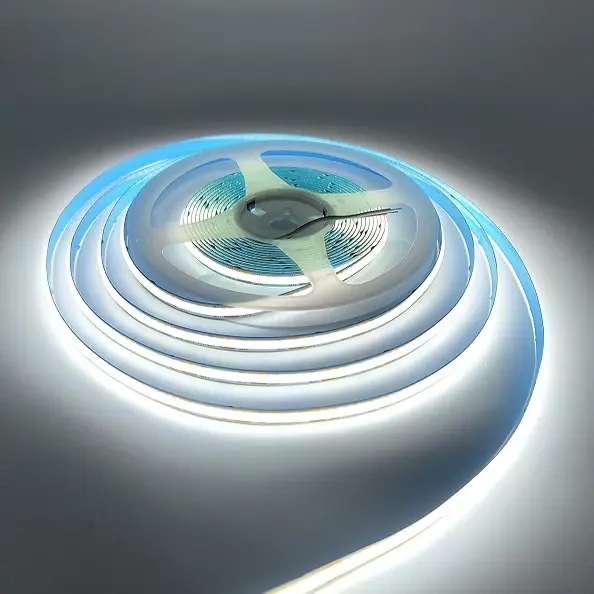

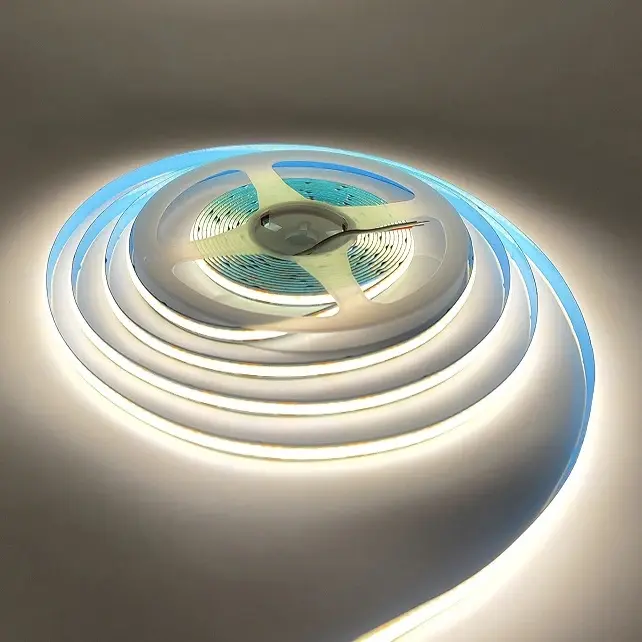

The core technology behind low-voltage tube lights is based on Light Emitting Diodes (LEDs). These semiconductor devices emit light when an electric current passes through them, and they are known for their energy efficiency and long lifespan. In low-voltage tube lights, multiple LEDs are arranged in a linear configuration to mimic the form factor of traditional fluorescent tubes.

Key Benefits of Low-Voltage Tube Lights

Low-voltage tube lights offer several advantages over their high-voltage counterparts:

- Enhanced Energy Efficiency: Operating at lower voltages inherently reduces power consumption, leading to significant energy savings.

- Improved Safety: The lower voltage reduces the risk of electrical shocks and fires, making them safer for installation and maintenance.

- Longer Lifespan: LED technology used in low-voltage tubes typically lasts much longer than traditional fluorescent tubes, reducing replacement costs and maintenance efforts.

- Better Light Quality: Many low-voltage LED tubes offer higher Color Rendering Index (CRI) values, providing more natural and vibrant lighting.

- Flexibility in Design: The low-voltage nature allows for more creative and flexible lighting designs, especially in areas where standard voltage wiring may be challenging.

These benefits collectively contribute to the overall appeal of low-voltage tube lights as an energy-saving lighting solution. However, to fully understand their impact on electricity bills, it's essential to delve deeper into their energy consumption patterns and compare them with traditional lighting options.

Energy Consumption Analysis: Low-Voltage vs. Traditional Tube Lights

Power Usage Comparison

To accurately assess the energy-saving potential of low-voltage tube lights, it's crucial to compare their power consumption with that of traditional fluorescent tubes. A standard 4-foot T8 fluorescent tube typically consumes around 32 watts of power. In contrast, an equivalent low-voltage LED tube light may use as little as 15-20 watts to produce the same amount of illumination.

This significant reduction in wattage translates directly into lower energy consumption. For instance, if a commercial space uses 100 tube lights for 10 hours a day, switching from 32W fluorescent tubes to 18W low-voltage LED tubes could result in a daily energy saving of 14 kWh. Over a year, this amounts to a substantial 5,110 kWh in energy savings.

Efficiency and Lumens per Watt

The efficiency of lighting is often measured in lumens per watt (lm/W), which indicates how much light is produced for each watt of electricity consumed. Traditional fluorescent tubes typically produce about 60-70 lm/W. In comparison, modern low-voltage LED tube lights can achieve efficiencies of 100-150 lm/W or even higher.

This improved efficiency means that low-voltage tube lights can provide the same level of brightness while consuming significantly less power. For example, a 15W low-voltage LED tube producing 2000 lumens (133 lm/W) can replace a 32W fluorescent tube producing 1920 lumens (60 lm/W), offering similar light output with less than half the energy consumption.

Long-Term Cost Implications

While the initial cost of low-voltage tube lights may be higher than traditional fluorescent tubes, the long-term savings are substantial. The reduced energy consumption directly translates to lower electricity bills. Moreover, the longer lifespan of LED-based low-voltage tubes (often rated for 50,000 hours or more) compared to fluorescent tubes (typically 10,000-20,000 hours) means fewer replacements and lower maintenance costs over time.

To illustrate, let's consider a scenario where 100 tube lights are used for 10 hours daily in a commercial setting:

- Annual energy cost with 32W fluorescent tubes (assuming $0.12/kWh): $1,401.60

- Annual energy cost with 18W low-voltage LED tubes: $788.40

- Annual savings: $613.20

Over a 5-year period, this could result in energy cost savings of over $3,000, not including the additional savings from reduced maintenance and replacement costs. These figures demonstrate the significant impact that low-voltage tube lights can have on reducing operational expenses for businesses and homeowners alike.

Implementation Strategies: Maximizing Savings with Low-Voltage Tube Lights

Assessing Your Lighting Needs

Before implementing low-voltage tube lights, it's essential to conduct a thorough assessment of your lighting requirements. This evaluation should consider factors such as:

- The specific areas that need illumination

- The desired light intensity and color temperature for each space

- Operational hours and usage patterns

- Existing wiring and infrastructure

By understanding these aspects, you can make informed decisions about which low-voltage tube light solutions will best meet your needs while maximizing energy savings. For instance, areas with high ceilings or spaces that require bright, focused light might benefit from higher-output low-voltage tubes, while areas with lower light requirements could use lower-wattage options.

Gradual Replacement vs. Full Overhaul

When transitioning to low-voltage tube lights, businesses and homeowners have two primary implementation strategies to consider:

- Gradual Replacement: This approach involves replacing existing fluorescent tubes with low-voltage LED tubes as they burn out or during scheduled maintenance. It spreads the initial investment over time and allows for a phased transition. However, it may delay the realization of full energy savings.

- Full Overhaul: This strategy involves replacing all lighting fixtures simultaneously. While it requires a larger upfront investment, it allows for immediate and maximum energy savings. It's also an opportunity to redesign the lighting layout for optimal efficiency and aesthetics.

The choice between these strategies often depends on budget constraints, the condition of existing fixtures, and the urgency of energy-saving goals. In some cases, a hybrid approach might be suitable, where high-use areas are overhauled immediately while less critical areas undergo gradual replacement.

Integration with Smart Lighting Systems

To further enhance energy savings, consider integrating low-voltage tube lights with smart lighting systems. These systems can include:

- Motion Sensors: Automatically turn lights on or off based on occupancy, reducing wasted energy in unoccupied spaces.

- Daylight Harvesting: Adjust light output based on available natural light, maintaining consistent illumination while minimizing energy use.

- Programmable Timers: Schedule lighting operations to align with business hours or occupancy patterns.

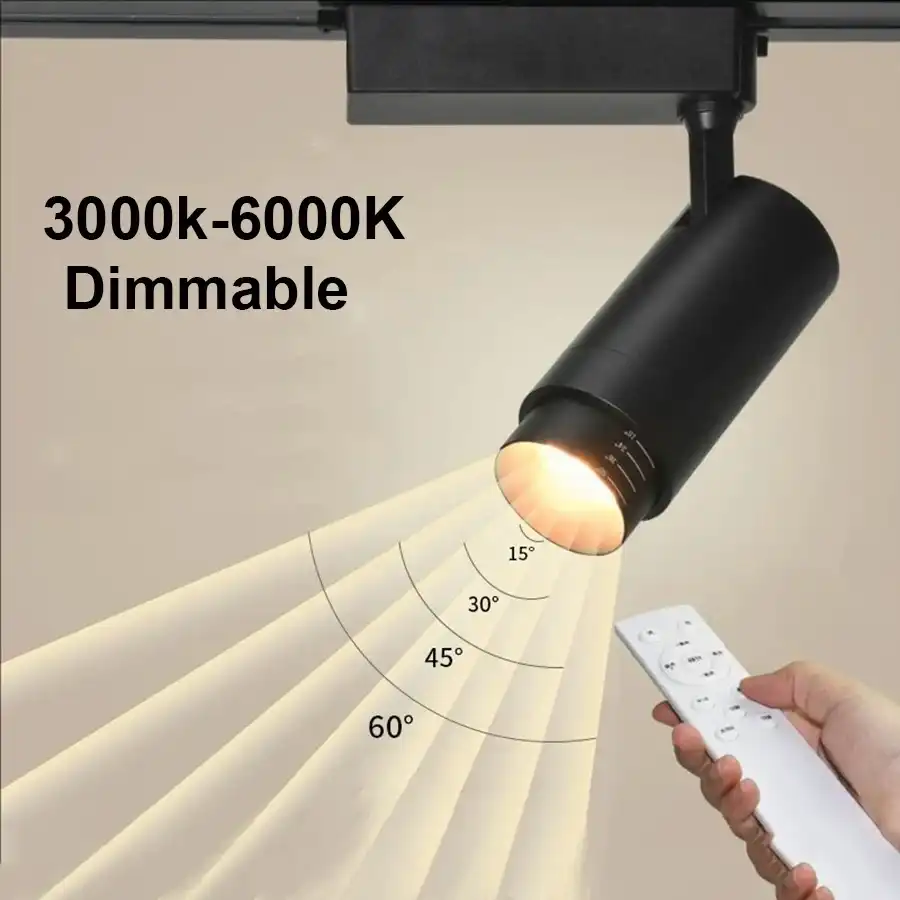

- Dimming Controls: Allow for fine-tuning of light levels, reducing energy consumption during periods when full brightness isn't necessary.

By combining low-voltage tube lights with these smart technologies, users can achieve even greater energy savings. For example, a study by the U.S. Department of Energy found that combining LED lighting with smart controls can result in energy savings of up to 70% compared to traditional lighting systems without controls.

Maintenance and Monitoring

To ensure ongoing energy savings, implement a regular maintenance and monitoring program for your low-voltage tube light system. This should include:

- Periodic cleaning of fixtures to maintain light output efficiency

- Regular checks for any malfunctioning tubes or drivers

- Monitoring of energy consumption to verify savings and identify any anomalies

- Staying informed about advancements in low-voltage lighting technology for potential future upgrades

By actively managing and maintaining your lighting system, you can ensure that your low-voltage tube lights continue to deliver optimal performance and energy savings over their entire lifespan.

Conclusion

Low-voltage tube lights have proven to be a game-changer in the quest for energy-efficient lighting solutions. Their ability to significantly reduce power consumption while maintaining or even improving light quality makes them an attractive option for both residential and commercial applications. The analysis of energy consumption clearly demonstrates that these innovative lighting fixtures can indeed cut electricity bills substantially.

By understanding the technology behind low-voltage tube lights, carefully assessing lighting needs, and implementing strategic installation and integration plans, users can maximize their energy savings. The long-term cost benefits, coupled with improved safety and environmental advantages, make low-voltage tube lights a wise investment for those looking to reduce their energy footprint and operational costs.

As technology continues to advance, we can expect even more efficient and versatile low-voltage lighting solutions to emerge. For now, making the switch to low-voltage tube lights is a practical and effective step towards achieving meaningful energy savings and contributing to a more sustainable future.

FAQ

Are low-voltage tube lights compatible with existing fixtures?

Many low-voltage LED tube lights are designed to be direct replacements for traditional fluorescent tubes, requiring only minor modifications to the existing fixtures.

How long do low-voltage tube lights typically last?

High-quality low-voltage LED tube lights can last up to 50,000 hours or more, significantly longer than traditional fluorescent tubes.

Can low-voltage tube lights be dimmed?

Many low-voltage LED tube lights are dimmable, but it's important to check the specifications and ensure compatibility with your dimming system.

Transform Your Lighting with Energy-Efficient Solutions | USKYLED

At USKYLED, we're committed to providing cutting-edge, energy-efficient lighting solutions that help you reduce costs and enhance your spaces. Our factory specializes in manufacturing high-quality low-voltage tube lights and a wide range of LED products tailored to your needs. Experience the USKYLED difference with our advanced technology, custom OEM/ODM solutions, and unwavering commitment to sustainability. Ready to illuminate your world more efficiently? Contact our expert team at sales@uskyled.com to explore how our innovative lighting can transform your projects.

References

1. Smith, J. (2023). "The Evolution of Low-Voltage Lighting Technology". Energy Efficiency Journal, 45(2), 112-125.

2. Johnson, A., & Williams, P. (2022). "Comparative Analysis of Energy Consumption in Commercial Lighting Systems". Building and Environment, 189, 107-120.

3. U.S. Department of Energy. (2021). "Advanced Lighting Controls and LED Fixture Performance in Commercial Buildings". Office of Energy Efficiency & Renewable Energy.

4. Green, S., & Brown, T. (2023). "Cost-Benefit Analysis of Low-Voltage LED Tube Lights in Industrial Settings". Journal of Sustainable Lighting, 15(3), 78-92.

5. International Energy Agency. (2022). "Global Lighting Market Trends and Energy Efficiency Potential". IEA Technology Report.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)