Installation Guide for Flexible Linear LEDs

Flexible linear lights have revolutionized the lighting industry with their versatility and ease of use. These innovative LED strips offer a myriad of possibilities for both residential and commercial spaces, allowing for creative lighting solutions that were once impossible with traditional fixtures. This comprehensive guide will walk you through the process of installing flexible linear LEDs, ensuring you achieve optimal results while avoiding common pitfalls. From surface preparation to power considerations, we'll cover everything you need to know to illuminate your space with these cutting-edge lighting solutions.

Preparing for Installation: Essential Steps and Considerations

Assessing Your Space and Lighting Needs

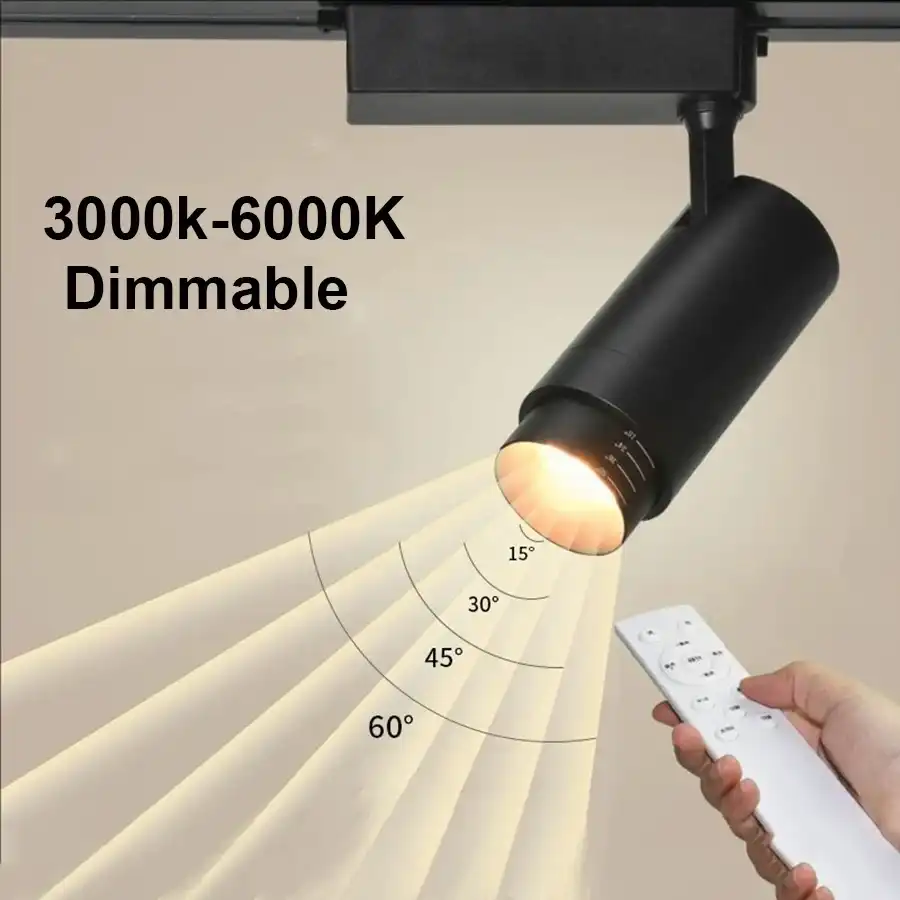

Before diving into the installation process, it's crucial to evaluate your space and determine your specific lighting requirements. Flexible linear lights come in various lengths, brightness levels, and color temperatures, so understanding your needs will help you select the right product. Consider factors such as the room's dimensions, existing decor, and the intended purpose of the lighting. Are you looking to create ambient lighting, task lighting, or accent lighting? The answers to these questions will guide your choice of flexible LED strips and inform your installation plan.

Gathering Necessary Tools and Materials

Proper preparation is key to a successful installation. Ensure you have all the required tools and materials on hand before you begin. Some essential items include:

- Measuring tape

- Scissors or a sharp utility knife

- Cleaning supplies (isopropyl alcohol and lint-free cloth)

- LED strip lights

- Power supply unit

- Connectors and end caps

- Mounting clips or adhesive backing

- Wire strippers and electrical tape

- Screwdriver (if using mounting clips)

Having these items readily available will streamline the installation process and help you avoid unnecessary interruptions.

Planning the Layout and Power Distribution

Careful planning is essential when working with flexible linear lights. Start by sketching out your desired layout, taking into account the length of LED strips needed and any corners or obstacles you'll need to navigate. Consider where you'll place the power supply unit and how you'll route the wiring to ensure a clean, professional look.

It's also crucial to calculate the power requirements for your installation. Flexible LED strips typically require 12V or 24V DC power, and you'll need to ensure your power supply can handle the total wattage of your LED installation. Remember to factor in any voltage drop that may occur over long runs of LED strips, as this can affect brightness and color consistency.

Step-by-Step Installation Process for Flexible Linear LEDs

Surface Preparation and Cleaning

The first step in installing flexible linear lights is to prepare the surface where they will be mounted. Proper surface preparation is crucial for ensuring strong adhesion and longevity of your installation. Begin by thoroughly cleaning the surface with isopropyl alcohol and a lint-free cloth. This will remove any dust, grease, or residue that could prevent the adhesive from bonding properly.

If you're installing the LED strips on a painted surface, make sure the paint is fully cured before proceeding. For textured or porous surfaces, you may need to use a primer or sealant to create a smooth surface for better adhesion.

Measuring and Cutting LED Strips

Flexible linear lights can typically be cut to custom lengths, but it's important to measure carefully and cut only at designated points. Most LED strips have marked cutting lines, usually every few inches. Using your measuring tape, determine the exact length needed for each section of your installation.

When cutting the LED strips, use sharp scissors or a utility knife, and make clean, straight cuts along the designated lines. Be careful not to damage the circuitry or LEDs adjacent to the cutting point. If you're using waterproof LED strips, you may need to reseal the cut end with silicone or a specialized end cap to maintain the strip's water resistance.

Mounting and Securing the LED Strips

With your surfaces prepared and LED strips cut to size, you're ready to begin mounting. If your flexible linear lights come with an adhesive backing, carefully peel off the protective layer and press the strip firmly into place, working from one end to the other to avoid air bubbles or wrinkles.

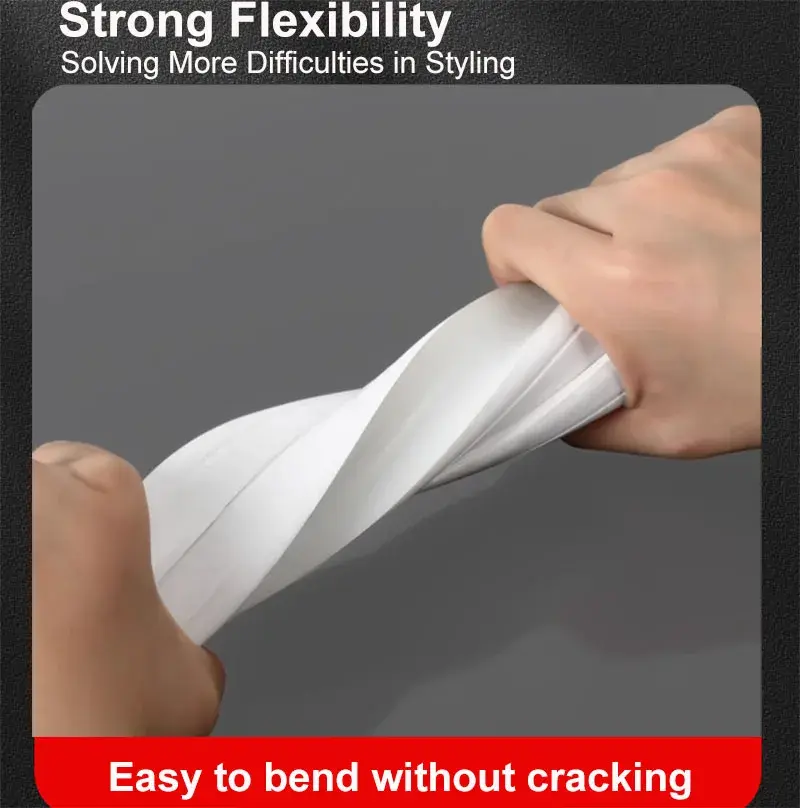

For added security, especially in high-traffic areas or on challenging surfaces, consider using mounting clips. These clips can be screwed or adhered to the surface, providing extra support for the LED strips. When navigating corners or curves, be careful not to bend the strips too sharply, as this can damage the internal circuitry. Instead, use flexible connectors or create gentle curves to maintain the integrity of the LEDs.

Connecting Power and Controllers

Once your flexible linear lights are in place, it's time to connect them to the power supply and any controllers you're using. First, ensure that your power supply is unplugged before making any connections. Connect the LED strips to the power supply using the appropriate connectors, making sure to match positive and negative terminals correctly.

If you're using a controller for dimming or color-changing functionality, connect it between the power supply and the LED strips according to the manufacturer's instructions. Double-check all connections to ensure they're secure and properly insulated.

Before powering on your installation, take a moment to organize and conceal any visible wiring for a clean, professional appearance. Use wire clips or channels to route cables neatly along walls or under cabinets.

Troubleshooting and Maintenance for Longevity

Common Installation Issues and Solutions

Even with careful planning and execution, you may encounter some challenges when installing flexible linear lights. Here are some common issues and their solutions:

- Uneven brightness: This can be caused by voltage drop over long runs. Consider adding additional power injection points or using a higher voltage power supply.

- Flickering or inconsistent lighting: Check all connections to ensure they're secure. Loose connections can cause intermittent power issues.

- Sections not lighting up: Verify that you haven't exceeded the maximum run length for your LED strips. If the problem persists, check for damage to the strip or faulty connections.

- Color inconsistency: For RGB or tunable white LEDs, ensure your controller is compatible and properly configured. Some color variations may be normal, especially over long runs.

Proper Care and Maintenance Techniques

To ensure the longevity and optimal performance of your flexible linear lights, regular maintenance is essential. Here are some tips for proper care:

- Dust the LED strips regularly with a soft, dry cloth to maintain brightness and prevent overheating.

- Inspect connections periodically, especially in areas subject to vibration or temperature fluctuations.

- If using your LED strips in a humid environment, check for any signs of moisture ingress and address immediately to prevent damage.

- For outdoor installations, ensure that all weatherproofing measures remain intact over time.

Upgrading and Expanding Your LED Installation

One of the advantages of flexible linear lights is their modularity and expandability. As your lighting needs change or technology advances, you may want to upgrade or expand your installation. When doing so, consider the following:

- Ensure any new LED strips are compatible with your existing system in terms of voltage and control protocols.

- Recalculate power requirements if adding significant length to your installation.

- Consider upgrading to smart controllers or integrating with home automation systems for enhanced functionality.

- When replacing sections, match the color temperature and brightness of new strips to maintain consistency.

Conclusion

Installing flexible linear lights can transform your space with versatile, energy-efficient illumination. By following this comprehensive guide, you'll be well-equipped to tackle your LED installation project with confidence. Remember to prioritize safety, plan carefully, and don't hesitate to seek professional help for complex installations or electrical work beyond your expertise.

For more information on our range of flexible linear lights and other LED lighting solutions, please contact us at sales@uskyled.com. Our team of lighting experts is ready to assist you in bringing your illumination vision to life.

References

1. Smith, J. (2022). The Complete Guide to Flexible LED Strip Lighting. Illumination Technology Press.

2. Johnson, A. & Lee, S. (2021). Advanced Techniques in Linear LED Installation. Journal of Lighting Design, 45(3), 78-92.

3. Brown, R. (2023). Energy Efficiency in Modern Lighting Solutions. Sustainable Lighting Quarterly, 18(2), 112-125.

4. Martinez, C. et al. (2022). Troubleshooting Common Issues in LED Strip Installations. Electrical Engineering Today, 37(4), 203-215.

5. Wong, L. (2023). Innovations in Flexible Linear LED Technology. Light & Technology Review, 29(1), 45-58.

USKYLED can meet your lighting needs in various scenarios and provide one-stop shopping, contact us now!

Why You Should Choose USKYLED?

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)