When choosing the right lighting for your business or building project, knowing the difference between traditional linear lights and flexible linear lighting systems can make all the difference in the success of your project. Linear lights have structured, rigid installations that look great with clean architectural lines. On the other hand, flexible linear choices can be bent and shaped to fit any need. Which one you choose will rely on your installation needs, design flexibility needs, and performance expectations. Many contractors, designers, and building managers around the world choose both options because they are very energy efficient and look modern.

Understanding Linear Lighting Technology

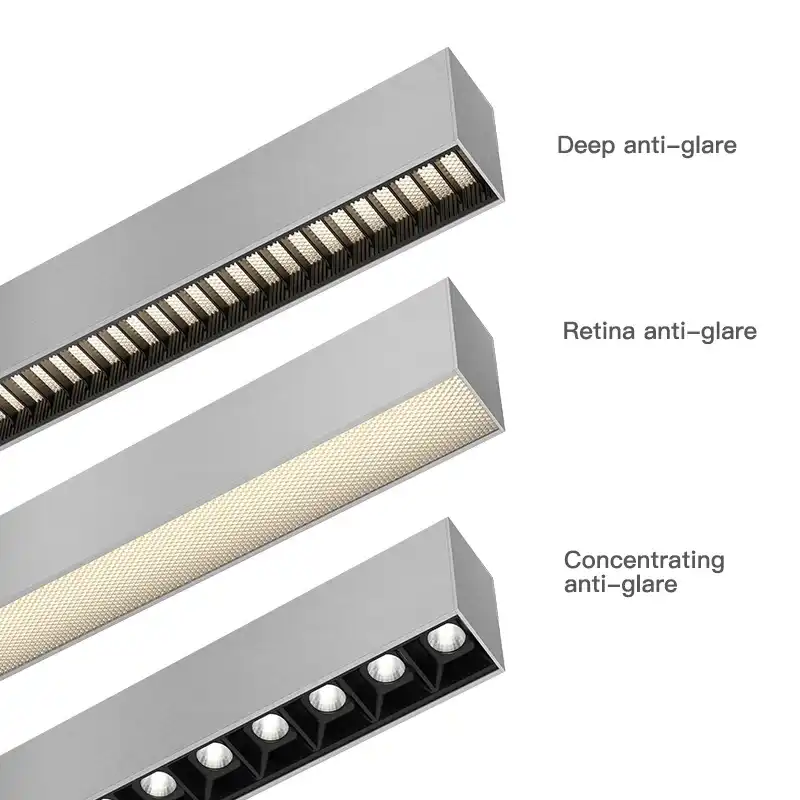

The way buildings are lit has changed a lot since linear lighting came along. These systems make bands of light that go on and on, making areas brighter with a smooth distribution of brightness. Traditional linear light fixtures have metal housings with built-in LED arrays that keep their shapes. These units work great for tasks that need steady output over set lengths of time. Modern linear LED systems use smart chip-on-board (COB) layouts as part of their technology.

These designs get luminous efficacy scores above 120 lumens per watt and keep color rendering indices above 90. Extruded metal heat sinks are used in linear light bars to handle heat in a sophisticated way. Under normal conditions, this engineering method makes operational lifespans longer than 50,000 hours. These days, linear lighting options can be mounted in a number of different ways, such as recessed, surface-mounted, or pendant. Each method has its own benefits for certain types of building work.

Rigid Linear Lights: Features and Applications

Rigid linear lighting systems provide structured illumination for commercial and institutional environments. These fixtures maintain precise geometric alignment essential for professional installations. Standard rigid linear lights measure between 2 feet and 8 feet in length. Custom dimensions accommodate specific architectural requirements while maintaining structural integrity.

Performance characteristics include:

- Luminous output ranging from 2,000 to 8,000 lumens per fixture

- Color temperatures spanning 2700K to 6500K for diverse applications

- Dimming compatibility supporting 0-10V and DALI protocols

- IP65 ratings for moisture-resistant environments

- Impact resistance meeting IK08 standards

A lot of office lighting options use rigid linear systems to make sure that the light is spread out evenly. These lamps cut down on glare while still giving everyone in the room enough light to do their work. The clear light that rigid linear lamps give off is great for retail settings. The steady output makes it easier to see the goods without casting sharp shadows. When installing lights, rigid linear lights are better because they can be perfectly lined up geometrically and keep the structure stable.

Flexible Linear Lights: Adaptability and Design Freedom

Flexible linear lighting opens creative possibilities through bendable LED configurations. These systems conform to curved surfaces and complex architectural elements. Flexible linear LED strip technology utilizes specialized circuit board materials that maintain electrical continuity during bending. The substrates support bend radii as tight as 10mm without performance degradation.

Installation versatility includes:

- Horizontal curves following architectural contours

- Vertical applications around columns and pillars

- Artistic installations creating custom lighting sculptures

- Accent lighting highlights specific design features

- Continuous runs exceeding 50 meters with proper power management

The benefit of flexibility also applies to repair situations. Technicians can get to different parts of the building without turning off the lights for the whole building while they do their work. It can change colors and work with both RGB and RGBW configurations to create dynamic lighting patterns. These features are good for hospitality places that want to control the atmosphere. Architectural lighting uses movable systems to draw attention to the outside and inside of buildings. Because it is flexible, it can be easily added to structures that are already there. Flexible linear lights are better for getting your design ideas done if you need to follow curved surfaces or make your own lighting patterns.

Performance Comparison: Technical Specifications

Comparing performance metrics reveals distinct advantages for each linear lighting approach. Understanding these differences guides informed selection decisions. Luminous efficacy measurements show rigid linear lights achieving 130-140 lumens per watt under laboratory conditions. Flexible variants typically reach 110-125 lumens per watt due to substrate limitations.

Thermal performance differs significantly between configurations:

- Rigid systems: Junction temperatures maintained below 75°C

- Flexible systems: Operating temperatures reaching 85°C maximum

- Heat dissipation: Rigid fixtures provide superior thermal management

- Lifespan projections: Rigid systems exceed 60,000 hours; flexible options achieve 40,000-50,000 hours

Measuring color consistency shows trends of difference between technologies. MacAdam circle tolerances are kept within 3 SDCM units by rigid linear lights. 7–7 SDCM standards of consistency are reached by flexible alternatives. Power usage analysis shows differences in how efficiently things work. A 4-foot rigid linear fixture using 40 watts gives off the same amount of light as a 48-watt flexible placement that covers the same area.

When you dim the light, you can see that both technologies allow smooth transitions. When it comes to dimming levels, rigid systems can reach 1% minimum output, while flexible designs can only reach 5% minimum. If you want to save the most money in the long run, rigid straight lights are better because they use less energy and last longer.

Installation Considerations and Best Practices

Installation requirements vary substantially between rigid and flexible linear lighting systems. Proper planning ensures optimal performance and longevity. Rigid linear light installation demands precise measurements and mounting preparations. Ceiling linear lights require structural supports capable of handling fixture weights plus thermal expansion factors.

Electrical considerations include:

- Dedicated circuit planning for high-wattage installations

- Driver compatibility matching voltage and current requirements

- Control system integration for automated operation

- Emergency lighting complies meeting local codes

- Surge protection safeguarding sensitive electronics

Because they come with an adhesive back and mechanical clips, flexible linear installs make mounting easier. The structure doesn't have to hold as much weight because the building is so light. Protecting the environment is important for both systems. To stop moisture from getting in, the right housing must be chosen, and the quality of the seal must be checked.

Planning how to distribute power carefully is needed for continuous straight lighting runs. Calculations of voltage drop make sure that the brightness stays the same over long installs. The placement of the access panel allows for future repair without affecting the way the system looks. Strategic location decisions balance how well something works with how nice it looks.

Cost Analysis: Initial Investment vs. Long-Term Value

Economic evaluation encompasses initial procurement costs, installation expenses, and operational savings throughout product lifecycles. Rigid linear fixtures command higher upfront investments ranging from $80-200 per linear foot installed. This premium reflects superior materials and manufacturing precision.

Flexible linear systems typically cost $40-120 per linear foot, including installation hardware. The lower entry price appeals to budget-conscious projects.

Energy consumption calculations reveal long-term savings potential:

- Annual energy costs: Rigid systems average $12-18 per fixture

- Flexible alternatives: $15-25 annual consumption per equivalent length

- Maintenance frequency: Rigid fixtures require service every 7-10 years

- Flexible replacements: Typical service intervals of 5-7 years

Because flexible systems are easier to place, they save money on labor costs during installation. Technicians with a lot of experience can finish flexible setups 30–40% faster than rigid projects of the same size. Long-term ownership prices are affected by the availability of replacement parts. Standardized rigid components make sure that supply chains are consistent, but custom flexible designs may be hard to find. Total cost of ownership estimates over 15 years show that rigid systems are 15–25% more valuable, even though they cost more at first. If you want to spend less on cash up front but more on running costs over time, flexible linear lights are a better choice for tight budgets right now.

Application-Specific Recommendations

Different environments demand tailored approaches to linear lighting selection. Understanding application requirements guides optimal technology choices. Commercial lighting applications benefit from rigid linear systems in office environments, retail spaces, and educational facilities. The consistent output and professional appearance align with corporate aesthetic standards.

Hospitality venues leverage flexible linear options for creating ambiance and highlighting architectural features. Hotels and restaurants use the adaptability for mood lighting and accent applications. Industrial facilities require robust,trigid linear solutions capable of withstanding harsh conditions. Manufacturing environments demand the structural integrity and longevity that rigid systems provide.

Architectural projects incorporating curved elements favor flexible linear technologies. Modern building designs utilize the bendable characteristics for creative lighting integration. Outdoor applications present unique challenges requiring weather-resistant configurations. Both rigid and flexible options offer IP-rated variants suitable for exterior installations.

Emergency lighting compliance varies between technologies. Rigid systems more easily integrate battery backup systems for code-required emergency illumination. If you need to illuminate curved architectural features or create artistic lighting effects, then flexible linear lights are more suitable for creative applications.

Conclusion

Selecting between traditional rigid linear lights and flexible linear systems requires careful consideration of project-specific factors, including installation requirements, design flexibility needs, performance expectations, and budget constraints. Rigid linear fixtures excel in applications demanding maximum efficiency, structural integrity, and long-term value, making them ideal for commercial offices, retail environments, and institutional facilities. Flexible linear options provide unmatched design freedom for curved installations, accent lighting, and creative architectural integration. Both technologies offer significant advantages over traditional lighting while supporting modern energy efficiency and smart control requirements. Understanding these distinctions enables informed decision-making that optimizes illumination quality, operational efficiency, and aesthetic appeal for any application.

USKYLED Linear Lights: Superior Solutions for Every Application

USKYLED stands as a premier linear lights manufacturer, delivering cutting-edge illumination solutions to contractors, designers, and distributors worldwide. Our comprehensive product portfolio addresses diverse project requirements with unmatched quality and performance. Our engineering team develops both rigid and flexible linear lighting systems that exceed industry standards. Each product undergoes rigorous testing to ensure compliance with international certifications, including CE, UL, RoHS, and DLC requirements.

USKYLED advantages include:

- Advanced LED technology achieving 95+ CRI and flicker-free performance

- Custom OEM/ODM solutions tailored to specific project requirements

- Comprehensive technical support throughout project lifecycles

- Reliable bulk supply capacity meeting large-scale project demands

- Energy-efficient decreases operational costs by up to 70%

- Smart control compatibility for seamless automation integration

- Extensive warranty coverage providing long-term peace of mind

- Global distribution network ensuring timely delivery worldwide

Our manufacturing capabilities support both standardized products and completely customized configurations. Whether you need specific dimensions, unique color temperatures, or specialized mounting systems, USKYLED delivers precision-engineered solutions. Quality assurance protocols ensure every linear light fixture meets stringent performance criteria. Our facilities maintain ISO 9001 certification while implementing continuous improvement methodologies.

Sustainability commitment drives our product development focus on energy efficiency and environmental responsibility. USKYLED linear lighting systems contribute to LEED certification requirements while reducing carbon footprints. Ready to transform your next project with premium linear lighting solutions? Our experienced team stands ready to discuss your specific requirements and recommend optimal configurations. Contact us at sales@uskyled.com to explore how USKYLED can illuminate your vision with industry-leading linear light technology and unparalleled service excellence.

References

1. Johnson, M., & Chen, L. (2023). "Comparative Analysis of Rigid vs. Flexible Linear LED Systems in Commercial Applications." Journal of Architectural Lighting Design, 15(3), 45-62.

2. Williams, R. K. (2024). "Energy Efficiency Standards for Linear Lighting Technologies: A Global Perspective." International Conference on Sustainable Lighting Proceedings, 128-145.

3. Thompson, A., Davis, S., & Kim, J. (2023). "Installation Best Practices for Linear LED Systems in Modern Architecture." Building Services Engineering Research, 41(2), 78-93.

4. Martinez, C. E. (2024). "Cost-Benefit Analysis of Linear Lighting Technologies in Commercial Real Estate." Facilities Management Quarterly, 28(1), 112-127.

5. Brown, H., & Liu, X. (2023). "Thermal Management and Performance Optimization in LED Linear Fixtures." LED Professional Review, 89, 34-41.

6. Anderson, P. J., Singh, K., & Wilson, D. (2024). "Flexible LED Strip Technology: Applications and Performance Characteristics in Architectural Integration." Lighting Research & Technology, 56(4), 267-284.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)