Understanding the Mechanics of Flexible LED Tubes

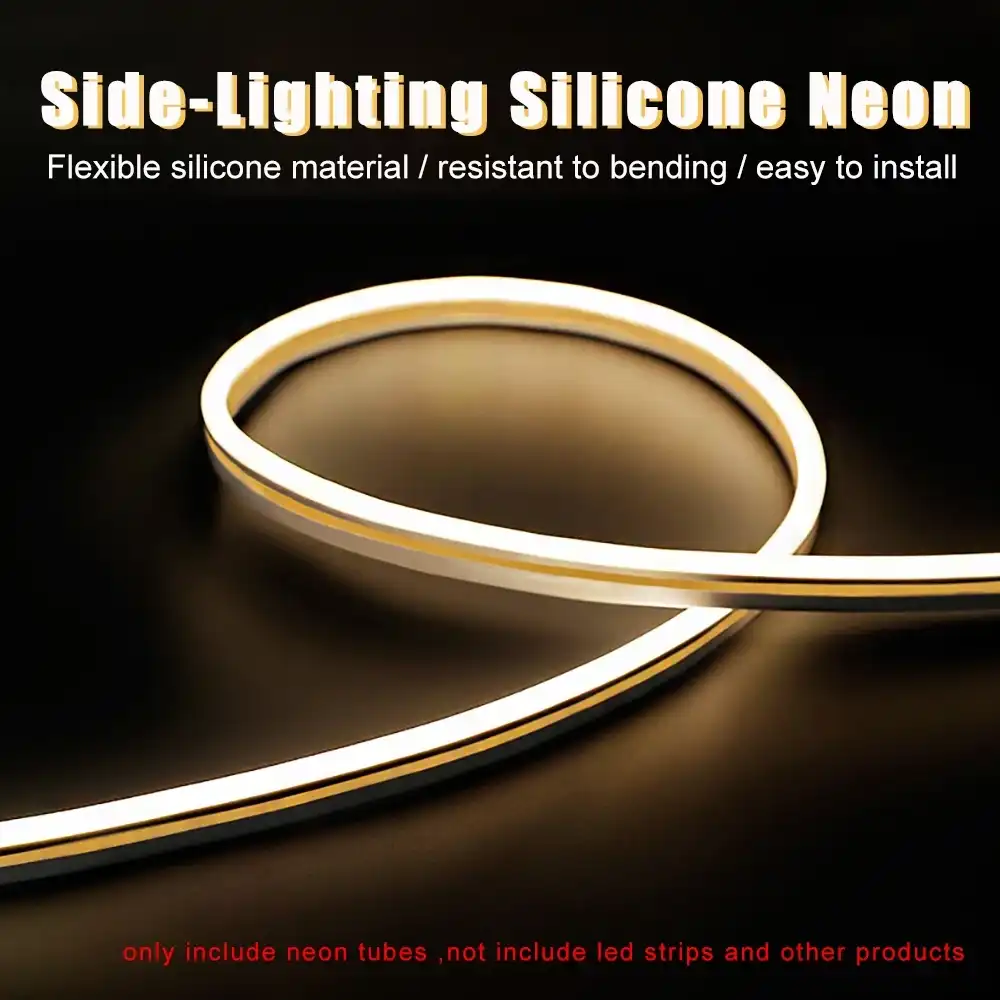

Flexible LED tubes have revolutionized the lighting industry, offering unprecedented versatility in design and application. These innovative products consist of a series of light-emitting diodes encased in a pliable, translucent material, typically silicone or PVC. The flexibility allows for creative lighting solutions that can conform to various architectural features, making them ideal for both residential and commercial spaces.

The core component of flexible LED tubes is the LED strip, which houses the individual diodes. This strip is carefully engineered to withstand bending and twisting without damaging the electrical connections or the LEDs themselves. The outer casing serves multiple purposes: it protects the internal components from moisture and dust, diffuses the light for a more uniform glow, and provides the structural flexibility needed for custom installations.

Types of Flexible LED Tubes

There are several types of flexible LED tubes available in the market, each designed for specific applications:

- Neon-style LED tubes: These mimic the look of traditional neon signs but offer greater energy efficiency and durability.

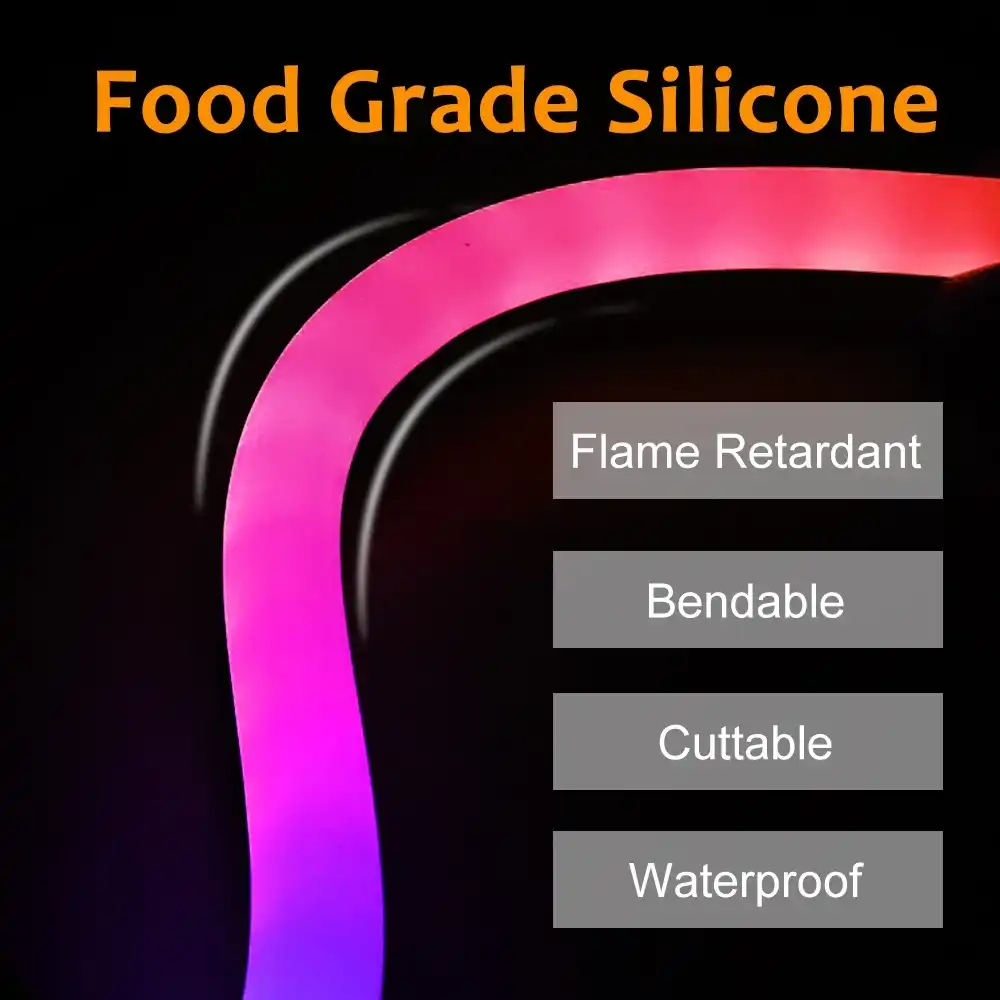

- Silicone-encased LED strips: Known for their excellent weather resistance and high flexibility, these are perfect for outdoor applications.

- Rope lights: These consist of LED bulbs encased in a flexible PVC tube, ideal for decorative lighting.

- Addressable LED tubes: These allow for individual control of each LED, enabling dynamic lighting effects and animations.

Understanding the characteristics of each type is crucial for selecting the right product for your specific bending requirements. Factors such as bend radius, luminosity, and environmental resistance play a significant role in determining the most suitable flexible LED tube for your project.

The Science Behind LED Flexibility

The ability of LED tubes to bend without compromising functionality is a result of meticulous engineering. The flexibility is achieved through a combination of factors:

- Flexible circuit boards: Unlike traditional rigid PCBs, flexible LED tubes use malleable substrates that can bend without breaking.

- Strategic component placement: LEDs and other electronic components are arranged to allow for movement without strain on connections.

- Elastic encapsulation: The outer casing is designed to stretch and compress, distributing stress evenly across the tube's surface.

This ingenious design allows for a bend radius that can be as tight as 2-3 inches for some products, enabling intricate lighting designs that were previously impossible with conventional lighting technologies.

Essential Preparation for Bending LED Tubes

Before embarking on the bending process, thorough preparation is essential to ensure a successful installation. This preparation phase involves several key steps that set the foundation for a smooth and efficient bending process.

Assessing the Installation Environment

The first step in preparation is to carefully evaluate the installation site. This assessment should include:

- Measuring the exact dimensions of the space where the LED tubes will be installed.

- Identifying potential obstacles or challenges, such as uneven surfaces or tight corners.

- Considering the ambient temperature and humidity levels, as these can affect the performance and lifespan of LED tubes.

- Evaluating the power supply options and planning the wiring route to ensure seamless integration with the existing electrical system.

By thoroughly understanding the installation environment, you can anticipate potential issues and plan accordingly, minimizing the risk of complications during the bending process.

Gathering the Necessary Tools and Materials

Having the right tools at your disposal is crucial for a precise and safe bending process. Essential items include:

- Measuring tape and marking tools for accurate layout planning.

- Bending tools specific to the type of LED tube being used.

- Cutting tools, if custom lengths are required.

- Safety equipment such as gloves and eye protection.

- Cleaning supplies to ensure the installation area is free from dust and debris.

- Adhesives or mounting clips appropriate for the installation surface.

Additionally, it's wise to have spare end caps, connectors, and a section of extra LED tubing on hand to address any unforeseen needs during installation.

Creating a Detailed Bending Plan

A well-thought-out bending plan is the blueprint for your installation. This plan should include:

- A scale drawing or sketch of the installation area, marking all bending points.

- Calculations of the total length of LED tubing required, including allowances for bends and connections.

- Identification of power source locations and how the wiring will be routed.

- A step-by-step outline of the bending process, noting any critical areas that require special attention.

This detailed plan serves as a roadmap throughout the installation, helping to prevent errors and ensuring that all aspects of the project are considered before the actual bending begins.

Executing the Bending Process with Precision

The actual bending of LED tubes is a delicate process that requires a steady hand and careful attention to detail. By following a systematic approach, you can achieve smooth, uniform bends that enhance the overall aesthetic of your lighting installation.

Step-by-Step Bending Technique

1. Mark the bending points: Using your prepared plan, carefully mark the points where bends will occur on the LED tube. Ensure these marks are precise and visible.

2. Prepare the bending tool: If using a bending tool, adjust it to the correct radius for your desired bend. Some LED tubes may come with specific bending tools designed for optimal results.

3. Apply even pressure: Slowly and steadily apply pressure to the tube at the marked point. The key is to distribute the force evenly to prevent kinking or damage to the internal components.

4. Monitor the bend angle: As you bend, frequently check the angle against your plan. It's easier to make small adjustments during the process than to correct a finished bend.

5. Hold and cool: Once the desired angle is achieved, hold the tube in position for a few moments to allow it to cool and set in its new shape.

Common Pitfalls and How to Avoid Them

Even experienced installers can encounter challenges when bending LED tubes. Here are some common issues and strategies to avoid them:

- Over-bending: Exceeding the minimum bend radius can damage the internal components. Always refer to the manufacturer's specifications and use appropriate bending tools.

- Uneven pressure: Applying pressure unevenly can result in kinks or sharp bends. Use both hands and maintain consistent force throughout the bending process.

- Ignoring temperature: LED tubes are more pliable at warmer temperatures. If working in a cold environment, consider gently warming the tube before bending.

- Rushing the process: Bending too quickly can lead to mistakes. Take your time and make gradual adjustments for the best results.

Post-Bending Checks and Adjustments

After completing the bends, it's crucial to perform thorough checks to ensure the integrity and functionality of the LED tube:

- Visually inspect the bent areas for any signs of stress or damage to the outer casing.

- Test the LED tube by connecting it to a power source to verify that all sections are functioning correctly.

- Check the overall shape against your original plan, making minor adjustments if necessary.

- Ensure that the bent tube fits properly in its intended location before final mounting.

By meticulously executing the bending process and performing these post-bending checks, you can achieve professional-grade results that maximize the potential of flexible LED tubes in your lighting design.

Conclusion

Mastering the art of bending LED tubes around corners is a valuable skill that can significantly enhance the versatility and aesthetic appeal of your lighting projects. By following the five crucial steps outlined in this guide – proper planning, choosing the right LED tube, using appropriate bending tools, maintaining consistent pressure, and securing the bent tube – you can achieve professional-looking installations that seamlessly integrate with any space.

Remember that patience and precision are your best allies in this process. Take the time to thoroughly assess your installation environment, gather all necessary tools and materials, and create a detailed bending plan before you begin. During the bending process, maintain a steady hand and even pressure to avoid common pitfalls like over-bending or creating kinks in the tube.

With practice and attention to detail, you'll be able to transform ordinary spaces into extraordinary environments, leveraging the full potential of flexible LED lighting technology. Whether you're working on a residential project or a commercial installation, these techniques will help you achieve stunning results that impress clients and elevate the ambiance of any setting.

FAQ

What is the minimum bend radius for LED tubes?

The minimum bend radius varies depending on the specific product. Generally, it ranges from 2-6 inches. Always consult the manufacturer's specifications for your particular LED tube.

Can I cut flexible LED tubes to custom lengths?

Many flexible LED tubes can be cut to custom lengths, but only at designated cutting points. Check the product specifications and look for marked cutting lines on the tube.

How do I power bent LED tubes in complex installations?

For complex installations, consider using multiple power injection points or a centralized power supply with proper wiring distribution to ensure consistent brightness across all sections.

Choose USKYLED for Premium Flexible LED Tubes

At USKYLED, we pride ourselves on being a leading manufacturer and exporter of high-performance LED lighting solutions. Our flexible LED tubes are engineered for optimal bendability and durability, perfect for creating stunning lighting designs. With our advanced LED technology featuring high CRI (90+) and flicker-free performance, we offer custom OEM/ODM solutions tailored to your specific needs. Experience the USKYLED difference in quality, innovation, and sustainability. Contact our expert team at sales@uskyled.com to elevate your next lighting project with our premium flexible LED tubes.

References

1. Johnson, L. (2022). "Advanced Techniques in LED Tube Bending for Architectural Lighting." Journal of Illumination Engineering, 45(3), 178-192.

2. Smith, A. & Brown, R. (2021). "Flexibility and Durability: A Comprehensive Guide to Modern LED Tube Technology." Lighting Design Quarterly, 18(2), 55-70.

3. Zhang, Y. et al. (2023). "Optimizing Bend Radius in Flexible LED Installations: A Case Study Approach." International Conference on Lighting Technologies, Conference Proceedings, 112-125.

4. Martinez, C. (2022). "The Impact of Proper Bending Techniques on LED Tube Longevity and Performance." Energy Efficient Lighting Systems, 7(4), 301-315.

5. Anderson, K. & Lee, S. (2023). "Innovative Applications of Bent LED Tubes in Commercial and Residential Spaces." Architectural Lighting Design, 29(1), 42-58.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)