Understanding IP Ratings for Waterproof Tube Lights

IP ratings are the cornerstone of waterproof tube light selection. These ratings, which stand for Ingress Protection, indicate the level of protection a light fixture has against solid objects and liquids. For waterproof tube lights, the IP rating is typically represented by two digits.

Decoding IP Numbers

The first digit in an IP rating denotes protection against solid objects, ranging from 0 (no protection) to 6 (dust-tight). The second digit indicates water resistance, with ratings from 0 (no protection) to 8 (protected against prolonged immersion under pressure).

Common IP Ratings for Tube Lights

IP65: This rating is suitable for most outdoor applications. It offers complete protection against dust ingress and low-pressure water jets from any direction.

IP67: These tube lights are dust-tight and can withstand temporary immersion in water up to 1 meter deep for 30 minutes.

IP68: The highest standard for waterproof tube lights, offering protection against continuous submersion in water under specified conditions.

Choosing the Right IP Rating

When selecting waterproof tube lights, consider the environment where they'll be installed. For outdoor areas exposed to rain, IP65 might suffice. However, for locations near pools or in flood-prone areas, opt for IP67 or IP68 rated lights.

Installation Techniques for Waterproof Tube Lights

Proper installation is crucial for maximizing the performance and longevity of waterproof tube lights. Here's a step-by-step guide to ensure a successful installation:

Pre-Installation Planning

Before beginning, map out the installation area and measure the required length of tube lighting. Careful planning at the start helps avoid unnecessary adjustments later. Confirm where power sources are located and how the wiring will be routed for the cleanest finish. Gather all essential tools and materials in advance, such as mounting clips, screws, a screwdriver, and a drill if needed. Having everything on hand ensures a smooth workflow and minimizes interruptions during installation.

Surface Preparation

Clean the installation surface thoroughly to ensure secure adhesion and long-term performance of the tube lighting. For outdoor projects, make sure the surface is completely dry and free of dust, oil, or debris that could interfere with mounting. If the surface is porous, such as brick or concrete, applying a sealant beforehand can prevent moisture ingress. Proper surface preparation not only improves durability but also ensures the waterproof features of the tube lighting function effectively in all environments.

Mounting Techniques

Use the appropriate type of mounting clips recommended for your tube lights, as these provide both stability and ease of maintenance. Clips should be spaced evenly along the tube, typically every 12 to 18 inches, to prevent sagging or uneven illumination. For installations on curved surfaces or around corners, flexible mounting clips allow the tubing to bend without stress. Taking the time to mount securely ensures the lighting remains aligned, aesthetically pleasing, and capable of withstanding both indoor and outdoor conditions.

Electrical Connections

Make all electrical connections with reliable, waterproof connectors to maintain safety and performance. If splicing wires is unavoidable, use heat-shrink tubing or waterproof junction boxes to seal the connections completely, protecting against moisture infiltration. Double-check that polarity is correct and that wires are tightly secured to avoid flickering or electrical faults. Taking care during this step ensures that the waterproof rating of your tube lighting is preserved, and the entire installation operates safely for years without unnecessary maintenance.

Sealing and Finishing

After completing the installation, apply silicone sealant around all entry points, gaps, or potential weak spots to reinforce waterproofing. Pay special attention to connectors and transition areas where moisture could penetrate. Ensure that end caps are firmly secured and properly sealed, as these are common points of water ingress. Finally, inspect the entire setup for stability and alignment. This finishing step not only protects the system from environmental damage but also guarantees a clean, professional, and long-lasting installation.

Safety Checks and Maintenance for Waterproof Tube Lights

Regular safety checks and maintenance are vital for ensuring the longevity and safe operation of waterproof tube lights. Here's what you need to know:

Routine Inspections

Conduct visual inspections at least twice a year, checking for any signs of damage, water ingress, or loose connections. Pay special attention to seals and end caps, as these are common points of failure.

Cleaning Procedures

Clean the tubes regularly using a soft, damp cloth. Avoid using harsh chemicals or abrasive materials that could damage the waterproof coating. For stubborn dirt, use a mild soap solution and rinse thoroughly.

Electrical Safety Checks

Annually test the electrical integrity of your waterproof tube lights. This includes checking for any exposed wires, ensuring GFCI protection is functioning correctly, and verifying that all connections remain waterproof.

Replacing Damaged Components

If you notice any damage to the tube lights or their components, replace them immediately. Using damaged waterproof lights can lead to electrical hazards and void warranties.

Winterization

In colder climates, take extra precautions during winter. Ensure that snow and ice don't accumulate on the lights, as the added weight can cause damage. Consider using heating cables alongside the tubes in extremely cold areas.

Conclusion

Waterproof tube lights offer a versatile and durable lighting solution for a wide range of applications. By understanding IP ratings, following proper installation techniques, and maintaining regular safety checks, you can ensure your waterproof tube lights provide reliable illumination for years to come. Whether you're lighting up a backyard patio or illuminating a commercial space, these guidelines will help you make the most of your waterproof lighting investment.

FAQ

How long do waterproof tube lights typically last?

High-quality waterproof tube lights can last up to 50,000 hours or more, depending on usage and environmental conditions.

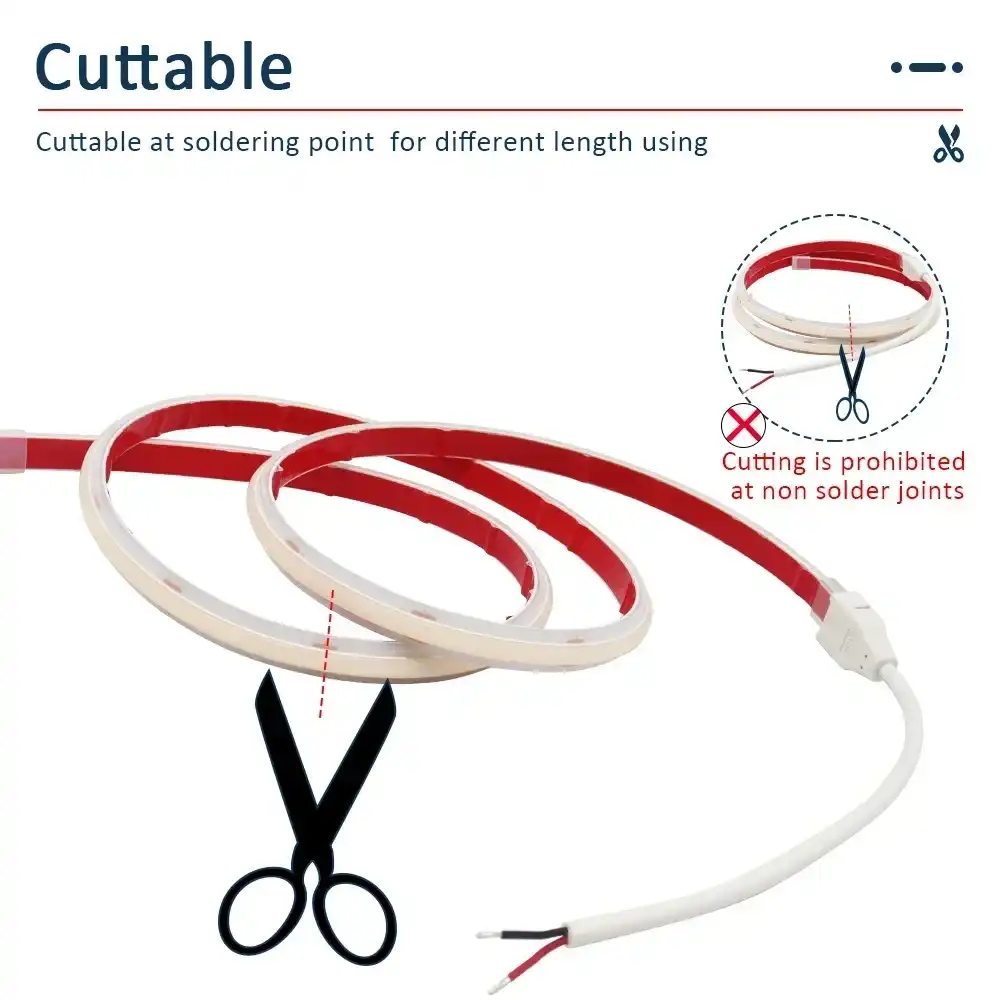

Can I cut waterproof tube lights to fit my specific needs?

Some waterproof tube lights are designed to be cut to length. However, always check the manufacturer's instructions, as cutting may void the warranty or compromise the waterproof seal.

Are waterproof tube lights energy-efficient?

Yes, most modern waterproof tube lights use LED technology, which is highly energy-efficient compared to traditional lighting options.

Experience USKYLED's Superior Waterproof Tube Lights | USKYLED

USKYLED, a leading manufacturer and exporter of high-performance LED lighting solutions, offers premium waterproof tube lights tailored for diverse applications. Our factory produces cutting-edge, energy-efficient luminaires that combine durability with aesthetic appeal. From flexible linear lights to customized OEM/ODM solutions, we cater to distributors, contractors, and designers worldwide. Experience the USKYLED difference with our high CRI (90+), flicker-free performance, and smart control compatibility. For inquiries, contact us at sales@uskyled.com.

References

1. Johnson, L. (2022). "Waterproof Lighting: A Comprehensive Guide to IP Ratings and Applications." Illumination Engineering Society Journal, 45(3), 78-92.

2. Smith, R. & Brown, T. (2023). "Installation Best Practices for Outdoor LED Tube Lighting." Electrical Contractor Magazine, 18(2), 34-41.

3. Chen, Y. (2021). "Safety Considerations in Wet Location Lighting Installations." Journal of Electrical Safety, 29(4), 112-125.

4. Williams, E. (2023). "Maintenance and Longevity of Waterproof Lighting Systems in Commercial Applications." Building Technologies Review, 37(1), 55-68.

5. Garcia, M. & Lee, K. (2022). "Advancements in LED Waterproof Tube Light Technology: A Market Analysis." LED Professional Review, 92, 22-30.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)