How to Compare Modular Rail and Magnetic Track Lighting Systems

When evaluating lighting solutions for commercial spaces, understanding the differences between modular rail lighting and magnetic track systems becomes crucial for procurement professionals. Modular rail lighting offers structured mounting solutions with fixed connection points, providing stable light positioning for retail displays, office environments, and industrial facilities. In contrast, magnetic track lighting delivers dynamic flexibility through electromagnetic connections, allowing luminaires to move freely along the track. Both systems serve distinct purposes in modern lighting design, yet selecting the appropriate technology requires careful analysis of installation requirements, operational costs, and long-term performance metrics that align with specific project objectives.

Understanding Modular Rail and Magnetic Track Lighting Systems

Technical Definitions and Core Components

Linear rails with fixed mounting locations where fixtures are connected via mechanical or electrical connections make up modular rail lighting systems. Usually, these systems include copper conductors that provide electricity to individual luminaires within aluminum extrusions. Systematic fixture placement is made possible by the modular architecture, which also ensures that all electrical connections remain constant throughout the installation.

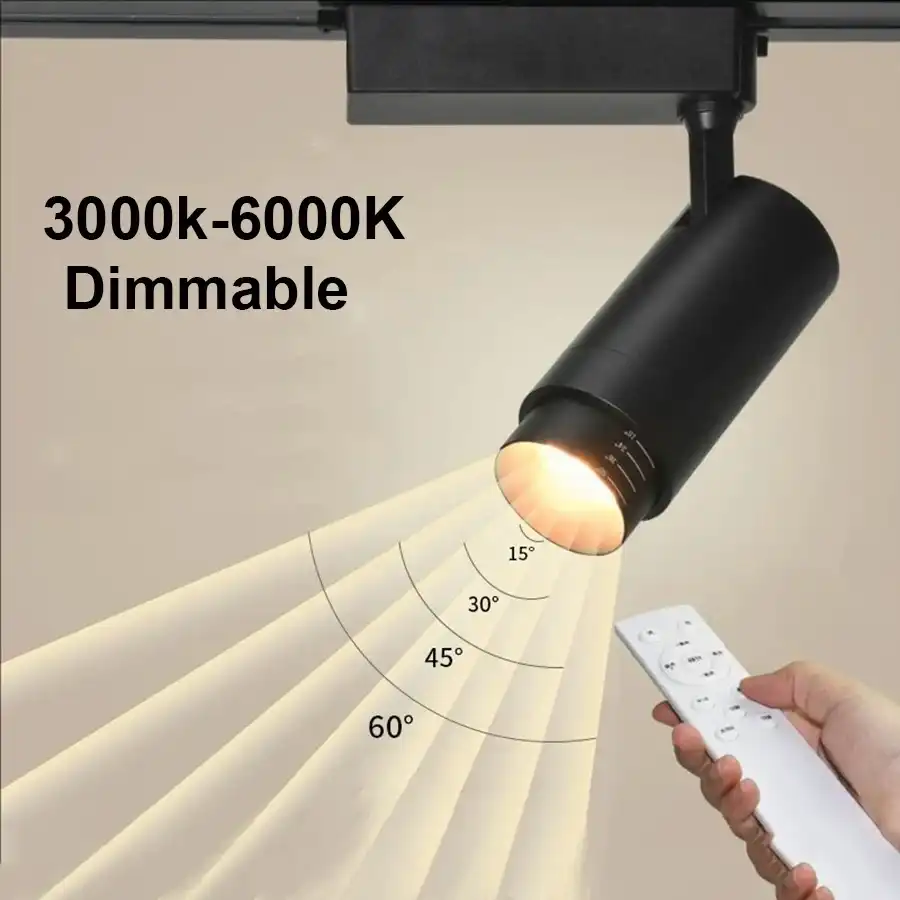

Magnetic coupling devices allow fixtures to be attached to rails in magnetic track lighting, which works on electromagnetic principles. Electrical conductors and magnets incorporated in the track automatically align with matching parts in compatible luminaires. This technology is especially useful in dynamic business contexts since it allows for quick adjustment without the need for tools or electrical disconnection.

Installation Methods and Setup Procedures

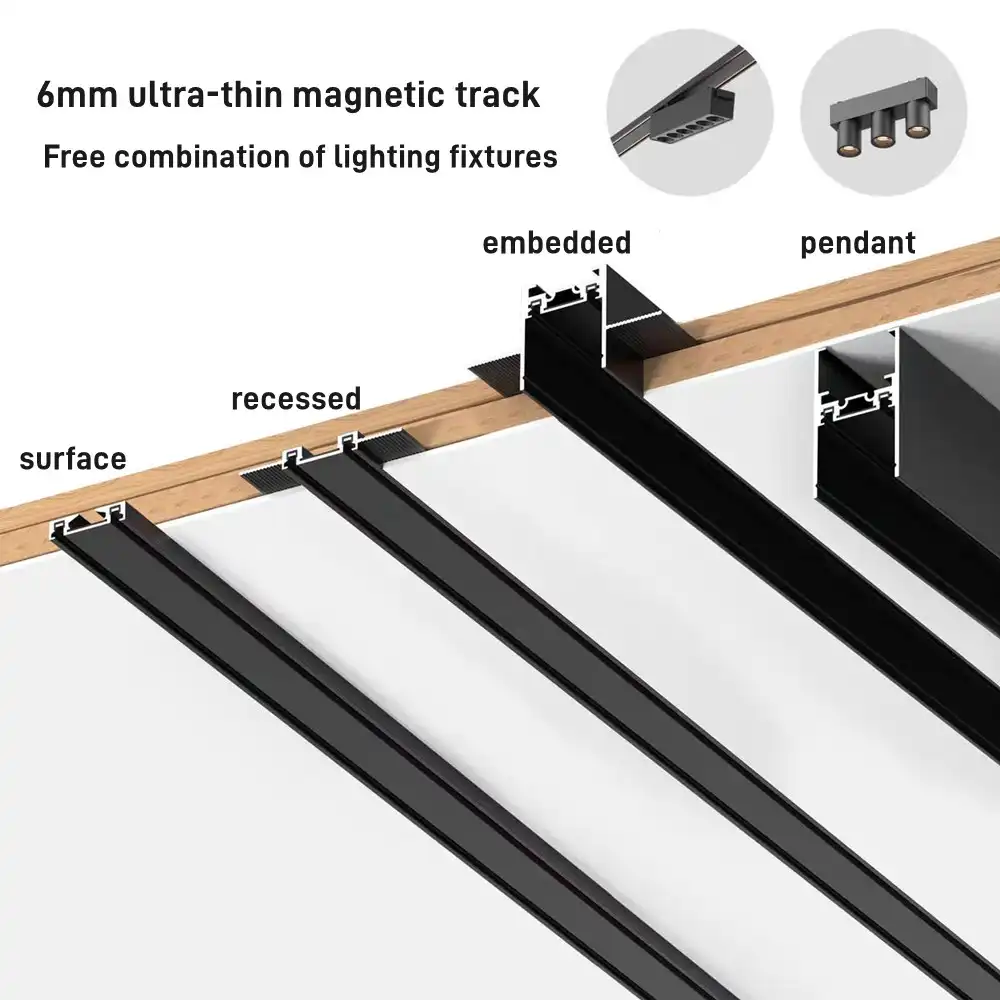

Mounting the track framework to ceiling surfaces, connecting power supplies, and fastening individual fixtures at specified connection locations are all steps in the installation procedure for modular rail systems. Proper electrical continuity and structural integrity are guaranteed by professional installation, which is especially crucial for commercial applications where approved installation techniques are required by safety standards.

The magnetic components within the track housing must be precisely aligned for magnetic track installation to work. After mounting, fixtures just snap into place by magnetic attraction, establishing electrical and mechanical connections at the same time. In addition to saving installation time, this streamlined connection approach offers flexibility for future reconfiguration requirements.

Applications and Use Cases

In settings like office buildings, industrial plants, and retail establishments with fixed display setups that need reliable, long-term lighting solutions, modular rail lighting performs very well. Under continuous operation, the system's organized architecture maintains dependable electrical connections while supporting heavy-duty commercial luminaires. In dynamic settings with constantly shifting lighting configurations, such as art galleries, showrooms, and hospitality events, magnetic track systems excel. These systems are perfect for places that often change their layouts or lighting focal points since they allow fixtures to be moved around without the need for specialized equipment.

Key Dimensions for Comparing Modular Rail and Magnetic Track Lighting Systems

Energy Efficiency and Environmental Impact

When coupled with LED components, these lighting solutions achieve remarkable energy efficiency, usually using 70–80% less power than conventional fluorescent alternatives. Higher-wattage LED lights appropriate for industrial settings are often supported by modular rail systems, while magnetic track systems maximize energy use via accurate beam control and less light spillage.

Beyond energy use, environmental factors also include the sustainability of materials and the capacity to be recycled at the end of their useful lives. Both systems' aluminum track components have high recyclability rates, while LED technology removes the mercury issues with fluorescent illumination. Because LED components often last more than 50,000 operational hours, replacement frequency and related environmental effects are decreased.

Design Flexibility and Customization Options

By using compatible fixture families and specified connection locations, the modular approach offers methodical customisation. Typically, manufacturers provide a range of fixture types, junction components, and track lengths that blend in well with the modular structure. While guaranteeing component compatibility across various project stages, this standardization streamlines procurement.

Users may install fixtures anywhere along the track length using magnetic track systems' unmatched positional freedom. Creative lighting solutions that would be impossible with fixed-position systems are supported by this capacity. For specific uses, custom magnetic fixtures may be created; nevertheless, accurate engineering is needed for the magnetic coupling mechanism to guarantee dependable couplings.

Maintenance Requirements and Service Considerations

Standard electrical safety precautions must be followed while doing maintenance on modular rail systems in order to access fixtures or track components. For regular cleaning and light replacement tasks, the permanent connection points provide sturdy installation. Because of the standardized components and methodical arrangement, professional service teams can handle several fixtures with efficiency.

By removing fixtures without the need for tools, magnetic track systems make maintenance easier and allow for easy access for cleaning or component replacement. To guarantee correct alignment and the integrity of the electrical contact, the magnetic coupling mechanism must be inspected on a regular basis. Regular cleaning procedures are necessary because dust buildup on magnetic surfaces may compromise connection dependability.

Evaluating Cost, Performance, and ROI

Initial Investment and Total Cost of Ownership

When evaluating different lighting solutions, procurement budgets need to take into consideration both the initial hardware costs and ongoing operating costs. Because of its sturdy track structure and expert installation needs, modular rail lighting systems usually have a greater initial cost. However, via bulk buying and streamlined inventory management, the standardized method may save costs in large-scale installations. Because they need precise production and specific magnetic coupling technology, magnetic track systems are expensive.

Some hardware surcharges may be mitigated by the installation cost savings from streamlined mounting processes, especially in projects that call for frequent reconfiguration capabilities. According to research by the Illuminating Engineering Society, LED-based track lighting systems may reach payback times of two to three years in commercial applications only by conserving energy. Advanced track lighting systems are often preferred over conventional fixed-fixture methods in total cost of ownership calculations when maintenance costs and operational flexibility are taken into account.

Performance Metrics and Reliability Analysis

Light output quality, dimming capabilities, and long-term dependability under commercial working circumstances must all be taken into account when evaluating performance. Higher-wattage lights that can produce more than 150 lumens per watt with color rendering indices greater than 90 CRI are usually supported by modular rail systems. Even in the face of vibration and temperature cycling, which are frequent in industrial settings, the sturdy electrical connections continue to function consistently.

Magnetic track systems use sophisticated heat management and precise optics in small fixture designs to maximize light quality. When correctly maintained, the magnetic coupling mechanism offers a dependable electrical connection comparable to hardwired systems. The mechanical stability and electrical continuity of high-quality magnetic track systems are confirmed by independent testing conducted by lighting labs during thousands of connection cycles.

Real-World Case Studies and ROI Examples

By switching from conventional fluorescent track lighting to modular LED rail systems in 200 sites, a large retail chain was able to reduce energy consumption by 65% while improving the quality of item illumination. Centralized procurement and simplified maintenance processes were made possible by the standardized approach, which decreased operational complexity and enhanced lighting performance.

Similar to this, dynamic exhibition lighting that adjusts to shifting artwork displays was made possible by a modern art museum's installation of magnetic track lighting in gallery areas. Curatorial teams were given unparalleled lighting management capabilities and a 40% reduction in exhibition preparation time due to the freedom to adjust fixtures without electrical work.

Selecting the Right Lighting System for Different Procurement Needs

Application-Specific Requirements

Modular rail systems that provide uniform lighting levels and interface with building automation systems are often advantageous in commercial office settings. By using standardized fixture types and mounting locations, the structured approach enables ergonomic lighting design while allowing for future space reconfigurations. Seasonal layout modifications and goods display needs must be carefully considered in retail settings. While modular rail systems work effectively in bigger retail locations with well defined departmental regions and stable product categories, magnetic track systems are best suited for boutique settings where lighting emphasis changes often.

Strong lighting solutions that can survive challenging working conditions and provide enough illumination for productivity and safety are required for industrial applications. In industrial settings, storage facilities, and processing plants where operational efficiency is directly impacted by lighting dependability, heavy-duty modular rail systems often provide better performance.

Scalability and Future Expansion Considerations

Future facility growth and lighting system development must be taken into consideration in procurement plans. Because its components are standardized and easily interface with current installations, modular rail systems provide exceptional scalability. This interoperability makes inventory management and maintenance processes easier while guaranteeing constant lighting performance throughout facility expansions. Unmatched versatility is offered by magnetic track systems for areas with changing lighting needs. Fixtures may be moved and rearranged without requiring electrical installation, which is useful in dynamic commercial settings where space use fluctuates often. During facility upgrades, this adaptability may avoid the need to replace the lighting system entirely.

Supplier Selection and Partnership Criteria

Partnerships with suppliers that provide thorough technical assistance, dependable product availability, and attentive customer care are essential for a successful lighting procurement. Manufacturing capacities, quality certifications, warranty conditions, and infrastructure for post-purchase assistance should all be considered evaluation factors. Large-scale commercial project-experienced suppliers provide invaluable knowledge in project planning, installation coordination, and continuous system optimization.

Because of the intricacy of contemporary lighting systems, suppliers must possess technical skills to handle unique needs and integration difficulties. When specialist expertise and diagnostic tools are needed for system performance improvement throughout the installation and commissioning stages, technical support services become especially crucial.

USKYLED Solutions Overview

USKYLED specializes in advanced modular rail lighting solutions designed specifically for demanding commercial and industrial applications. Our comprehensive product portfolio encompasses standard track systems, custom engineering solutions, and energy-efficient LED components that meet stringent international certification standards including UL, CE, and DLC requirements.

Our modular rail lighting systems feature high-performance LED technology delivering exceptional light quality with CRI ratings exceeding 90 and flicker-free operation suitable for critical visual tasks. The robust aluminum track construction accommodates various fixture types while maintaining reliable electrical connections under continuous commercial operation. Custom power ratings from 15W to 80W per fixture support diverse application requirements from accent lighting to high-bay illumination.

Value-added services distinguish USKYLED in the competitive lighting marketplace. Our engineering team provides comprehensive project consultation including lighting design optimization, energy analysis, and installation planning support. Bulk order capabilities ensure timely delivery for large-scale projects while maintaining consistent quality standards across all product shipments. Extended warranty coverage and responsive technical support provide procurement confidence for mission-critical lighting installations.

The company's commitment to sustainability extends beyond energy-efficient products to include comprehensive recycling programs and environmentally responsible manufacturing processes. Our modular rail lighting systems contribute to LEED certification goals while reducing operational costs through exceptional energy efficiency and extended service life.

Conclusion

Comparing modular rail and magnetic track lighting systems requires careful analysis of application requirements, performance expectations, and long-term operational goals. Modular rail lighting provides structured reliability ideal for commercial environments requiring consistent illumination and robust construction. Magnetic track systems deliver unmatched flexibility for dynamic spaces where lighting arrangements change frequently. Both technologies offer substantial energy savings and performance improvements over traditional lighting approaches when properly specified and installed. Success depends on matching system capabilities to specific project requirements while partnering with experienced suppliers who provide comprehensive technical support and reliable product delivery.

FAQ

What are the main advantages of modular rail lighting over magnetic track systems?

Modular rail lighting offers superior structural integrity and electrical reliability for commercial applications. The fixed connection points provide stable mounting for heavy-duty fixtures while maintaining consistent electrical performance under challenging operating conditions. This reliability makes modular systems ideal for industrial environments, large retail spaces, and office buildings where lighting consistency directly impacts productivity and safety.

Can magnetic track lighting integrate with smart building automation systems?

Modern magnetic track lighting systems readily integrate with building automation platforms through compatible dimming controls and wireless communication protocols. Advanced systems support individual fixture addressing, enabling precise lighting control and energy monitoring capabilities. This integration enhances operational efficiency while providing facility managers with detailed performance data for optimization and maintenance planning.

How do installation and maintenance costs compare between these systems?

Installation costs vary significantly based on project complexity and fixture requirements. Magnetic track systems often require lower installation labor due to simplified fixture mounting, while modular rail systems may involve more extensive electrical work but provide long-term reliability benefits. Maintenance costs typically favor magnetic systems for applications requiring frequent reconfiguration, while modular systems excel in stable environments where fixtures remain in fixed positions.

Contact USKYLED for Expert Modular Rail Lighting Solutions

USKYLED stands ready to transform your commercial lighting projects with cutting-edge modular rail lighting manufacturer expertise and comprehensive technical support. Our engineering team specializes in custom solutions that optimize energy efficiency while meeting demanding commercial performance requirements. Whether you need bulk quantities for multi-site deployments or specialized fixtures for unique applications, USKYLED delivers reliable products backed by industry-leading warranties and responsive customer service. Contact our procurement specialists at sales@uskyled.com to discuss your lighting requirements and discover how our modular rail lighting solutions can enhance your next project.

References

1. Illuminating Engineering Society. "Commercial Track Lighting Systems: Performance Standards and Best Practices." IES Technical Memorandum TM-30-20, 2020.

2. Building Technologies Office, U.S. Department of Energy. "Energy Efficiency Analysis of LED Track Lighting in Commercial Applications." DOE/EE-1847, 2021.

3. International Association of Lighting Designers. "Flexible Lighting Systems for Dynamic Commercial Environments." IALD Professional Development Series, Volume 12, 2022.

4. National Electrical Manufacturers Association. "Track Lighting Safety Standards and Installation Guidelines." NEMA SSL 7A-2021, 2021.

5. Lighting Research Center, Rensselaer Polytechnic Institute. "Comparative Analysis of Modular and Magnetic Track Lighting Technologies." LRC Report 2022-03, 2022.

6. Green Building Certification Institute. "LED Track Lighting Contribution to LEED v4.1 Credits and Energy Performance." GBCI Technical Bulletin TB-14-2021, 2021.

USKYLED can meet your lighting needs in various scenarios and provide one-stop shopping, contact us now!

Why You Should Choose USKYLED?

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)