If commercial builders in the US want to buy high-quality office lights, they can do so straight from China through well-known manufacturers, business-to-business sites like Alibaba, or LED lighting suppliers. China is the world leader in LED lighting because it has the most advanced manufacturing technology, the lowest prices, and the most flexible options. The biggest Chinese companies offer full OEM/ODM services, foreign certifications (UL, DLC, CE), and strong supply chains that are designed to work with business projects in North America. Direct buying lets you better control costs, make changes, and get access to the latest LED technology for modern offices.

Understanding the Global Office Lighting Market Landscape

The commercial lighting industry has undergone a remarkable transformation over the past decade. Energy-efficient LED solutions now dominate workspace illumination, replacing traditional fluorescent systems across corporate America. This shift reflects growing awareness of sustainable practices and operational cost reduction strategies.

Market Dynamics Driving Change

There is more and more pressure on commercial builders to make buildings that are energy-efficient and meet LEED approval standards. Modern office lighting systems need to provide the right amount of light for each job while also keeping the overall comfort level high. Technologies like smart lighting controls and daylight gathering are no longer extras; they are now required. As companies move toward more open workspaces, the need for office light fixtures that can be changed keeps growing. Open-plan offices need complex lighting systems that can handle different work areas and tasks. Ergonomic lighting has a direct effect on how productive and healthy employees are, which makes lighting design a very important investment.

Supply Chain Evolution

Global supply lines have changed to keep up with the fast progress in LED office lighting technology. Chinese companies have put a lot of money into research and development, and now their lighting products are just as innovative and high-quality as well-known Western names. Consolidation in manufacturing has led to economies of scale, which help business buyers by making prices more competitive. International standards have made the certification process easier, which makes it possible for products to work well in multiple markets. To meet the strict safety and efficiency standards in North America, quality control systems have changed over time.

Advantages of Sourcing Office Lights from China

China's position as the world's largest LED manufacturing hub offers distinct advantages for commercial builders. The country produces approximately 70% of global LED components and finished lighting products, creating an ecosystem of specialized suppliers and supporting industries.

Cost Effectiveness and Value Engineering

When compared to standard distribution channels, buying directly from Chinese manufacturers usually cuts costs by 30 to 50 percent. This lower price comes from cheaper labor, more efficient manufacturing on a large scale, and better integrated supply lines. Commercial makers can use the money they save to add high-end features like smart controls or better color temperature choices. When you work directly with a manufacturer, you can find value engineering possibilities. At reasonable prices, custom office lighting solutions become possible, letting builders make their projects stand out without breaking the bank.

Manufacturing Capabilities and Innovation

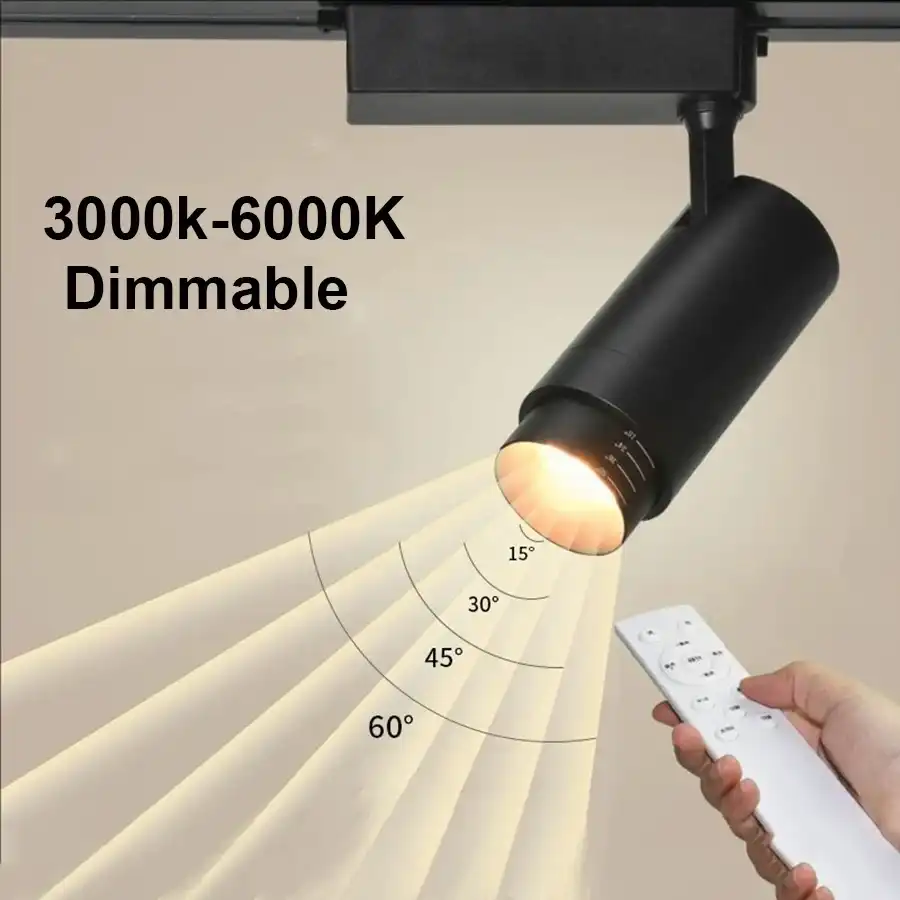

Chinese companies that make LEDs have developed advanced production methods that allow for both fast prototyping and mass production. Modern automated assembly lines make sure that the standard is always the same and that prices stay low. For world demand cycles, many factories have production schedules that run 24 hours a day, seven days a week. New lighting technologies are always being made at innovation centers in big manufacturing hubs. Smart office lighting systems, white solutions that can be adjusted, and lighting apps that focus on people often make their debut in Chinese facilities before they reach other markets.

Customization and OEM Services

Office light fixtures can be made in a lot of different ways thanks to flexible manufacturing methods. To meet architectural needs, builders can define specific sizes, mounting arrangements, and optical features. With private labeling services, builders can build brand recognition while still saving money. As companies try to get more foreign business, minimum order quantities (MOQs) have become more reasonable. For custom setups, many suppliers can now take orders as low as 100 to 500 units.

Evaluating Different Sourcing Channels

Commercial builders have multiple pathways for sourcing office lights from China. Each channel offers distinct advantages and considerations that impact project outcomes.

B2B Platform Procurement

Platforms like Alibaba, Global Sources, and Made-in-China.com provide access to thousands of verified suppliers. These marketplaces offer built-in communication tools, supplier verification systems, and transaction protection services. Advanced search filters help identify suppliers specializing in commercial office lighting applications. Supplier ratings and transaction histories provide valuable insights into reliability and performance track records.Trading Companies and Intermediaries

Trading companies serve as intermediaries between builders and manufacturers, offering several operational advantages. These entities typically maintain inventory, handle quality control, and manage logistics coordination. Established trading companies often represent multiple manufacturers, enabling product comparisons and consolidated shipments. They provide English-language support and understand North American business practices, streamlining communication processes.

Local Distributors with Chinese Partnerships

Some US-based distributors maintain direct partnerships with Chinese manufacturers while providing local support services. This hybrid approach combines cost advantages with domestic convenience factors. Local inventory availability reduces lead times for standard products while maintaining access to custom solutions through manufacturer partnerships. Technical support and warranty services remain domestically accessible.

Supplier Verification and Quality Assurance Strategies

Successful office lighting procurement requires systematic supplier evaluation and quality verification processes. Commercial builders must implement comprehensive screening procedures to ensure reliable partnerships.

Financial and Operational Assessment

Evaluate potential suppliers' financial stability through business registration verification, bank references, and trade credit reports. Established manufacturers typically maintain transparent financial records and professional business practices. Production capacity assessment ensures suppliers can meet project timelines and volume requirements. Factory audits, either in-person or through third-party services, provide insights into manufacturing capabilities and quality systems.

Certification and Compliance Verification

Verify that office light products carry appropriate certifications for North American markets. UL listing, DLC qualification, and Energy Star compliance represent minimum requirements for most commercial applications. Request certificates directly from certification bodies rather than relying solely on supplier documentation. Current certification databases allow real-time verification of product listings and compliance status.

Sample Testing and Validation

Implement systematic sample testing procedures before committing to large orders. Third-party testing laboratories can verify photometric performance, electrical safety, and environmental compliance. Establish clear acceptance criteria covering light output, color consistency, and mechanical construction quality. Document testing protocols to ensure consistent evaluation across different suppliers.

Quality Control Implementation

Develop quality control agreements that specify inspection procedures, acceptance standards, and corrective action protocols. Pre-shipment inspection services provide additional assurance for large orders. Random sampling procedures help identify potential quality issues before products reach job sites. Statistical quality control methods enable systematic monitoring of supplier performance over time.

Practical Procurement Considerations

Successful office lighting procurement requires careful attention to operational details that impact project timelines and budgets. Understanding common practices and potential challenges helps builders develop effective sourcing strategies.

Order Quantities and Pricing Structures

Minimum order numbers are very different between suppliers and types of products office lights. For standard office light fixtures, the minimum order quantity is usually 500 to 1000 units. For custom designs, the minimum order quantity may be 200 to 500 units. Usually, pricing models have more than one level based on the number of orders. Knowing the break points helps make procurement tactics work better for more than one project. A lot of suppliers will lock in prices for agreed-upon yearly volumes.

Payment Terms and Financial Protection

Standard payment terms include a 30% deposit and the remaining 70% due before the shipment. For bigger deals, letter of credit plans can be made. Trade assurance programs on B2B sites give businesses even more financial security. When dealing with a new seller, escrow services can help protect payments. When you do business with a seller more than once, they'll likely offer better terms.

Lead Times and Logistics Coordination

Lead times for production are usually between 15 and 30 days for standard goods and 25 to 45 days for custom configurations. Ocean shipping adds 15 to 25 days for deliveries to the West Coast and 25 to 35 days for deliveries to the East Coast. When you choose air freight, the travel time drops to 5–7 days, but the shipping costs go up a lot. For urgent project needs, hybrid shipping strategies can find a good mix between cost and time.

Common Procurement Challenges

Problems with communication can lead to misunderstandings about needs and specs. Technical models with lots of details and clear written instructions help keep interpretation mistakes to a minimum. Samples and final runs may not always be the same in terms of quality. Setting up staged payment plans that are linked to quality goals is a good way to keep suppliers accountable. Delivery delays can throw off project plans, especially when production is at its highest. Adding extra time to project schedules and keeping ties with backup suppliers lowers the risk.

Building Long-Term Supplier Partnerships

Sustainable success in office lighting procurement depends on developing strong supplier relationships that support ongoing business objectives. Strategic partnerships create mutual benefits that extend beyond individual transactions.

Performance Monitoring and Feedback

Set up a method for tracking performance that keeps an eye on things like on-time delivery, consistent quality, and quick communication office lights. Supplier scorecards that are updated regularly help find ways to improve and praise great performance. Give suppliers helpful comments that help them understand what the market wants and expects. When people work together to make things better, they often come up with new ideas that help everyone.

Technology Development Collaboration

Work with suppliers to find new lighting solutions that fit with what the market wants. Getting early access to new developments gives you an edge when bidding on and carrying out projects. Joint development projects for custom lighting solutions for offices can open up new ways to place a product in the market. In some market areas, exclusive agreements may give you a short-term edge over your competitors.

Strategic Volume Planning

Make yearly predictions of volume that will help suppliers plan their production capacity and get better price terms. A lot of the time, committed volume relationships let you get more services and help. Coordinate the time of purchases to get the most out of shipping consolidation and efficient production. Planning strategically lowers overall costs and raises the dependability of the supply chain.

Conclusion

US business builders can save a lot of money, make the lights exactly how they want them, and get access to cutting-edge LED technology by buying custom office lights from China. For success, you need to evaluate suppliers in a planned manner, ensure the standards are high, and build relationships strategically. As the global lighting market changes, it continues to support builders who work directly with manufacturers and set up strong procurement processes. Commercial builders can be successful in the long run in a market that is becoming more and more demanding if they use smart sourcing strategies that balance the need for quality with the need to save money.

Frequently Asked Questions

What certifications should office lights from China have for US commercial projects?

Office lights must carry a UL listing for electrical safety, a DLC qualification for energy rebate eligibility, and FCC compliance for integrated controls. Energy Star certification is preferred for government projects. California Title 24 compliance may be required for West Coast installations.

How long does it typically take to receive custom office lights from Chinese manufacturers?

Custom office lighting projects typically require 25-45 days for production plus 15-35 days for ocean shipping, depending on the destination port. Rush orders can be accommodated with air freight in 5-7 days, but at significantly higher costs. Sample production usually takes 7-10 days.

What are typical minimum order quantities for custom office light fixtures?

Minimum order quantities vary by complexity and manufacturer capabilities. Standard modifications often require 200-500 pieces, while completely custom designs may need 500-1000 units. Some suppliers accommodate smaller quantities at higher unit prices for testing purposes.

How can I verify the quality and reliability of Chinese office lighting suppliers?

Verify business licenses, certifications, and financial stability through official channels. Request customer references and conduct factory audits when possible. Third-party inspection services provide additional quality assurance. Start with smaller orders to evaluate supplier performance before committing to large volumes.

What payment methods are commonly accepted by Chinese office lighting manufacturers?

Most suppliers accept wire transfers, letters of credit, and trade assurance programs through B2B platforms. Payment terms typically range from 30-50% deposit with balance before shipment. Established relationships may offer extended payment terms or smaller deposit requirements.

Partner with USKYLED for Premium Office Lighting Solutions

USKYLED stands as your trusted office lights manufacturer, specializing in high-performance LED solutions for commercial builders across North America. Our comprehensive product portfolio includes energy-efficient linear lights, smart track systems, and architectural luminaires designed specifically for modern workspace applications. With advanced LED technology featuring 90+ CRI ratings, flicker-free performance, and smart control compatibility, our office lighting systems deliver superior illumination quality while reducing operational costs.

As an established LED manufacturer with extensive OEM/ODM capabilities, we customize designs to match your exact specifications and project requirements. Our streamlined production processes accommodate flexible minimum order quantities while maintaining competitive pricing for bulk procurement scenarios. International certifications, including UL, DLC, and Energy Star, ensure seamless compliance with North American standards.

Transform your commercial projects with cutting-edge office lighting technology backed by comprehensive technical support and reliable delivery schedules. Contact us at sales@uskyled.com to discuss your specific requirements and discover why leading commercial builders choose USKYLED for their office lighting needs.

References

1. Chen, Michael. "Global LED Lighting Market Analysis: Commercial Applications and Manufacturing Trends." International Lighting Review, vol. 45, no. 3, 2023, pp. 78-95.

2. Johnson, Sar Ah, ah, and David Park. "Supply Chain Strategies for Commercial Lighting Procurement." Building Systems Engineering Quarterly, vol. 28, no. 4, 2023, pp. 134-149.

3. Liu, We,i ,I and Jennifer Martinez. "Energy Efficiency Standards in Commercial Office Lighting Design." Sustainable Building Technologies Journal, vol. 12, no. 2, 2023, pp. 56-72.

4. Thompson, Robert. "Quality Assurance Protocols for International LED Lighting Procurement." Commercial Construction Management Review, vol. 33, no. 1, 2024, pp. 23-38.

5. Wang, Ele, N,en and Mark Stevens. "Cost Analysis of Direct vs. Distributor Sourcing for Commercial Lighting Projects." Facilities Management Economics, vol. 19, no. 3, 2023, pp. 112-127.

6. Anderson, Patricia. "Certification Requirements and Compliance Strategies for Imported Lighting Products." Electrical Safety and Standards Bulletin, vol. 41, no. 2, 2023, pp. 89-103.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)