The lighting market is developing quickly, and in 2026, flexible track lighting will be a game-changing option for both homes and businesses. These new kits are far more flexible than old rigid track systems, so companies may easily change the lighting configuration as their areas change. If you're a sourcing manager looking at innovative ways to buy things or an engineering contractor planning your next project, knowing about the best flexible track lighting solutions available this year may have a big effect on how well your project goes and how well your business runs in the long run.

Understanding Flexible Track Lighting Kits and Their Advantages

Track lighting systems have changed the way businesses light their spaces by giving them the ability to be flexible and moved around, something fixed lighting can't do. The main difference between flexible and rigid track systems is how they are built and how easy they are to install.

How Flexible Track Systems Work?

Flexible track lighting uses flexible rails constructed of special materials that keep the electrical circuit going while allowing curves and angles up to certain radii. These systems include modular parts including track sections, connections, power feeds, and fixture heads that can work with different types of LED technology. The flexible track's electrical conductors keep the electricity flowing steadily, no matter how the track is set up. This lets designers make curved paths, follow architectural elements, or work with unusual ceiling layouts.

Key Benefits for B2B Applications

The advantages of implementing flexible track lighting in commercial environments extend beyond simple aesthetic appeal. Energy efficiency represents a primary consideration for procurement managers, with modern LED-based flexible track systems achieving luminous efficacies exceeding 120 lumens per watt. This efficiency translates to substantial operational cost savings over the system's lifespan, particularly valuable for large-scale installations in retail environments, hospitality venues, and office complexes.

Design flexibility lets facility managers change the way the lights are set up without having to do a lot of rewiring or structural changes. This feature is quite useful in stores where the displays vary with the seasons or in offices that are changing their layouts. Because these systems are modular, they can be easily expanded or changed, which helps businesses grow and spaces change.

Industry Applications and Use Cases

Flexible track lighting works best in places where lighting has to change all the time. Retail stores may keep the room well-lit while also highlighting certain sections of product. These systems are used by hotels and restaurants to create mood lighting that can be changed for various times of day or special events. Manufacturing plants like the strong structure and the flexibility to give task lighting that matches the layout of the production line.

The Top Flexible Track Lighting Kits of 2026 – Detailed Comparisons

To choose the best flexible track lighting manufacturers, you need to look at a number of performance factors that directly affect B2B buying choices. There are a number of great solutions on the market right now, each with its own set of benefits for certain business uses.

Performance Specifications Analysis

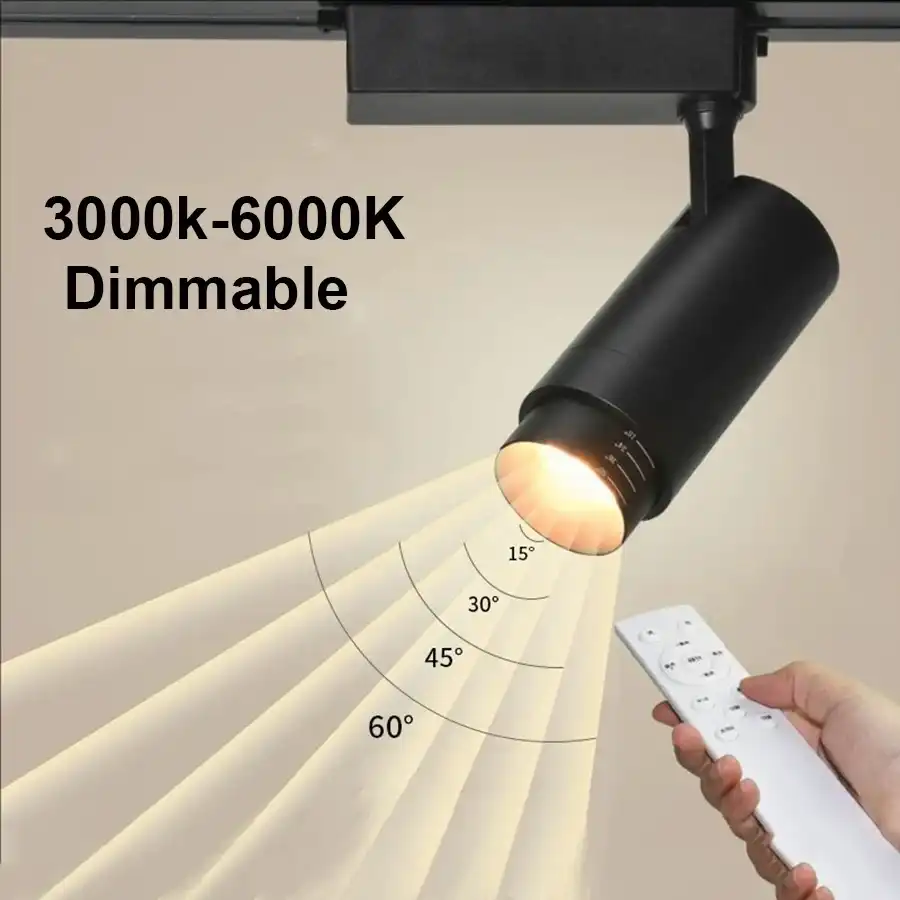

Luminous effectiveness is still the most important technical factor. The best manufacturers' current products have 130+ lumens per watt. Color temperature flexibility has grown a lot. Many systems now include adjustable white settings that can go from 2700K to 6500K in a single light. This adaptability allows the same technology to be used in both warm, welcoming settings and bright, industrial workstations.

Most high-end flexible track systems now include dimming and work with 0-10V, DALI, and wireless control protocols. This interoperability makes it easy to work with building management systems and smart lighting controls, which is very important for big commercial installations that need to be able to control everything from one place.

Leading Manufacturer Comparison

Premium brands stand out from the others by delivering better build quality, longer warranties, and better technical support. Systems with high-quality metal tracks that also regulate heat last longer than those with simple polymer tracks. The quality of the connectors has a big effect on how reliable the system is. Precision-engineered connections make sure that electrical contact and mechanical stability stay the same even after thousands of reconfigurations.

Different manufacturers provide different types of warranties. Some give regular 3-year warranties, while others offer extended 7-year warranties that cover both parts and labor. Extended warranty options are especially helpful for big commercial installations where system downtime may have a big effect on how the firm runs.

Customer Feedback and Performance Data

Facility managers and lighting contractors in the industry often say that simplicity of installation and long-term dependability are key considerations for success. Systems with tool-free connecting designs and lightweight track sections are best for projects that need to be changed often. Surveys of customer satisfaction show that business customers are more likely to be happy with systems that come with full technical assistance and easy-to-find replacement parts.

Installation and Maintenance Guide for Flexible Track Lighting Kits

To make flexible track lighting work well and last a long time, you need to plan ahead and follow best practices. Procurement managers can make smart choices regarding total cost of ownership when they know how to install and maintain things.

Installation Process and Requirements

The first step in professional installation is to look at the ceiling structure to figure out the best ways to attach things and how to spread the weight. Depending on the kind of track material and the weight of the fixtures, flexible track systems usually need support points every 24 to 48 inches. Local laws say that electrical connections must be safe. This frequently means that circuits must be big enough to handle the maximum expected load plus a 25% safety buffer.

When designing the layout of a track, you need think about the minimum curve radii requirements, which usually range from 12 to 36 inches, depending on how the track is built. Going beyond these limitations might damage the internal conductors or break the electrical connection. Professional installers use specific equipment to make sure that the curves are smooth and that the support spacing is correct throughout the installation.

Maintenance Best Practices

Regular maintenance keeps systems running smoothly and extends their life. Every month, visual inspections should look for evidence of stress, connection integrity, and fixture alignment on track segments. Cleaning every three months with the right non-conductive solutions gets rid of dust that might affect how well heat is released and how bright the light is.

Different manufacturers have different ways to replace parts, but they usually follow modular design principles that let field service technicians work without specific tools. Having extra connection and track pieces on hand cuts down on downtime during repair, which is especially critical for retail and hospitality settings where lighting problems may ruin the customer experience.

Professional Support Services

Many businesses profit from installation monitoring and commissioning services that the manufacturer provides. These services make sure that the right installation methods are used and that facility maintenance workers get training on site. Ongoing technical assistance includes the ability to diagnose problems from a distance and quickly replace parts. This is especially useful for multi-location business chains that need to keep lighting standards uniform throughout all of their locations.

Making the Right Purchase Decision – What B2B Buyers Should Know

When making strategic procurement selections, you need to carefully look at all the technical parameters, the total cost of ownership, and the capabilities of the suppliers. The market for flexible track lighting has a lot of possibilities, each with its own performance and price structure that may meet the needs of various businesses.

Technical Evaluation Criteria

In addition to basic lumens per watt measurements, modern commercial applications also need to take into account light quality metrics. For example, retail applications need Color Rendering Index (CRI) values over 90, video production environments need flicker-free operation, and specific task requirements need photometric distribution patterns that are optimized. Smart control integration lets you connect to building automation systems and energy management protocols.

For firms that are expanding or for projects that are being rolled out in stages, system scalability is very important. Long-term investment protection comes from having compatible expansion parts and consistent performance specs across several generations of the same product. Manufacturers who provide products that work with older systems give retrofit applications more options.

Pricing Models and Cost Analysis

Most of the time, flexible track lighting prices are based on tiers, with big reductions for big commercial orders. Volume pricing usually starts at 50 units, and purchases of more than 500 pieces may get even more reductions. Customization options, including changing the color temperature, beam angle, or adding branded lights, usually cost 15–30% more than the basic price. However, they may help businesses stand out in a big way.

When figuring up the total cost of ownership, you should consider energy use throughout the estimated lifetime, maintenance needs, and any reconfiguration expenses. Even though they cost more up front, high-efficiency systems with longer warranties sometimes provide better long-term value, especially for installations that need to run for a long time or are hard to get to.

Supplier Evaluation and Partnership Considerations

For commercial lighting projects to work, suppliers need to be reliable, provide good technical assistance, and be able to work together for a long time. Standard setups usually take 2 to 6 weeks to complete, but unique solutions might take 8 to 12 weeks, depending on how complicated the specifications are. Suppliers with warehouses and distribution networks in North America can get things to you quicker and make logistics easier for critical projects.

Technical support should include help with design before a sale, installation, and continuous maintenance. Suppliers who provide training programs for installation teams and facility maintenance workers are very helpful for big commercial deployments that need to follow the same rules at all sites.

USKYLED: Your Trusted Partner for Advanced Flexible Track Lighting Solutions

USKYLED is in the forefront of LED lighting innovation, providing high-quality flexible track lighting solutions that match the strict needs of businesses throughout the globe. Our whole range of products includes the latest track lighting technology made just for the changing demands of commercial lighting businesses, architectural firms, and engineering contractors in North America and abroad.

Advanced Technology and Superior Performance

Our flexible track lighting systems use the newest LED technology with CRI scores of over 90+, which makes colors look great in stores and for business use. Our innovative thermal management makes sure that the performance stays constant and the operating life is longer. The flicker-free performance and smart control compatibility make it easy to integrate with contemporary building management systems.

USKYLED's dedication to energy economy results in bright efficacies that fulfill strict commercial lighting regulations and save operating expenses by a large amount. All of our products meet all of the necessary certification requirements, including as UL, DLC, and Energy Star ratings. This makes it easy for commercial projects in a wide range of industries to have their specifications approved.

Customization and OEM Solutions

USKYLED knows that commercial lighting projects typically need customized solutions, therefore they provide a lot of customization options, including as custom color temperatures, beam angles, and branded fixture designs. Our OEM and ODM services let distributors and contractors sell unique items while keeping prices low thanks to our fast and efficient production procedures.

Our ability to handle bulk orders means that big commercial projects will always have guaranteed delivery times. Our technical support staff is also available to help with design and installation throughout the project lifespan. USKYLED is the best alternative for procurement managers looking for trusted, long-term lighting partners because of the high quality of its products and the assistance it offers.

Conclusion

The flexible track lighting market in 2026 has unparalleled prospects for commercial applications necessitating versatile, energy-efficient lighting solutions. When making buying selections, it's important to carefully look at technical standards, total cost of ownership, and the skills of the suppliers. Leading systems stand out because they are built better, come with a full guarantee, and have strong technical support services.

USKYLED's innovative flexible track lighting systems provide the appropriate mix of cutting-edge technology, customizable options, and dependable support services that today's commercial lighting specialists need. We promise to keep coming up with new ideas and helping our customers succeed, which guarantees the best lighting results for a wide range of business uses.

FAQ

Q1: What are the key differences between flexible and rigid track lighting systems?

A: Flexible track systems include rails that can bend so they can follow curved paths and architectural elements. Rigid systems, on the other hand, can only be set up in straight lines. Flexible systems provide for more design options, but they may cost a little more to start and need specific installation methods to maintain electrical continuity across curved areas.

Q2: How do energy efficiency ratings compare between LED flexible track lighting and traditional systems?

A: Modern LED flexible track systems provide 120–130+ lumens per watt, whereas classic halogen track lighting only gets 60–80 lumens per watt. This increase in efficiency means that energy use goes down by 40–60% but light quality and operational life are enhanced. Traditional systems last 2,000–5,000 hours, whereas these last 50,000 hours or more.

Q3: What customization options are available for commercial flexible track lighting projects?

A: You may choose the color temperature (2700K–6500K), the beam angle (15°–60°), the finish of the fixture, the brand of the components, and the mounting mechanism. Many manufacturers provide modular designs that make it simple to change things around, dim the lights, and connect to smart controls to satisfy the needs of certain business applications.

Partner with USKYLED for Your Flexible Track Lighting Needs

Ready to transform your commercial lighting projects with advanced flexible track lighting solutions? USKYLED combines innovative technology, competitive pricing, and exceptional support services to deliver lighting systems that exceed expectations. Our flexible track lighting manufacturer capabilities ensure custom solutions tailored to your specific requirements, while our experienced technical team provides comprehensive support throughout your project lifecycle. Contact us at sales@uskyled.com to discuss your flexible track lighting requirements and discover how our solutions can enhance your next commercial lighting project.

References

1. Chen, Michael. "Commercial LED Track Lighting Systems: Performance Analysis and Energy Efficiency Standards." Journal of Illuminating Engineering Society, Vol. 34, No. 2, 2024.

2. Rodriguez, Sarah et al. "Flexible Track Lighting Technologies: Comparative Analysis of Installation Methods and Long-term Performance." Lighting Design + Application Magazine, March 2024.

3. Thompson, David. "Energy-Efficient Commercial Lighting Solutions: Market Trends and Technology Developments in 2024." Commercial Building Energy Report, Annual Edition 2024.

4. Williams, Jennifer. "Track Lighting Systems for Commercial Applications: Design Considerations and Performance Metrics." Architectural Lighting Research Institute, Technical Report Series, 2024.

5. Kumar, Raj and Lisa Morgan. "LED Track Lighting Market Analysis: Technology Trends and Commercial Applications." International Lighting Review Quarterly, Volume 45, Issue 4, 2024.

6. Anderson, Robert. "Flexible Lighting Systems in Commercial Environments: Installation Best Practices and Maintenance Guidelines." Professional Lighting Contractors Association Technical Bulletin, 2024.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)