The Rise of Shenzhen as an Aluminum Profile Manufacturing Powerhouse

Shenzhen's change from a angling town to a flourishing mechanical center is nothing brief of momentous. The city's mechanical parks have been instrumental in this transformation, pulling in both household and universal companies looking for to use China's fabricating ability. When it comes to aluminum profiles, Shenzhen's mechanical parks offer a special combination of ability, progressed innovation, and cost-effectiveness.

State-of-the-Art Facilities for Aluminum Profile Production

The mechanical parks in Shenzhen brag cutting-edge offices committed to the generation of aluminum profiles. These parks are prepared with progressed expulsion presses able of creating complex cross-sectional shapes with tall accuracy, as well as state-of-the-art cutting apparatus that guarantees reliable lengths and clean edges. Surface treatment workshops utilize innovations such as anodizing, powder coating, and electrophoresis to improve solidness and aesthetics.

The consistent integration of these frameworks, combined with computerized fabric dealing with and strict handle checking, empowers producers to keep up uncommon consistency and effectiveness. As a result, OEM clients advantage from aluminum profiles that meet rigid worldwide guidelines whereas supporting speedier lead times and more noteworthy generation scalability.

Skilled Workforce and Technical Expertise

Shenzhen's mechanical parks are domestic to a exceedingly talented workforce with broad encounter in aluminum profile fabricating. The city’s long-standing accentuation on specialized instruction, professional preparing, and ceaseless proficient improvement has made a solid pool of engineers, professionals, and quality pros who get it the complexities of expulsion innovation. Their skill permits producers to accomplish tight resistances, exact surface medications, and predominant dimensional exactness.

Talented groups moreover exceed expectations at problem-solving and adjusting plans to meet challenging OEM necessities, whether for engineering outlines, mechanical components, or buyer gadgets. This solid specialized establishment guarantees that each organize of aluminum profile production—from amalgam choice to last inspection—is dealt with with uncommon competence and reliability.

Innovation and Research & Development Centers

Many of Shenzhen's mechanical parks house devoted R&D centers centered on progressing aluminum profile innovation. These offices work closely with colleges, testing research facilities, and worldwide industry accomplices to create modern combinations that make strides strength-to-weight proportions, erosion resistance, and formability. Analysts too investigate progressed expulsion strategies, warm break advances, and improved surface treatment forms to raise item execution.

Prototyping labs permit for quick experimentation and testing of unused plans, guaranteeing speedier development cycles. This collaborative environment cultivates persistent advancement, giving OEM clients get to to cutting-edge arrangements that move forward proficiency, solidness, and aesthetics. Such development guarantees Shenzhen remains a pioneer in next-generation aluminum profile manufacturing.

Advantages of Sourcing Aluminum Profiles from Shenzhen Industrial Parks

Procuring aluminum profiles from Shenzhen's industrial parks offers numerous benefits for OEM customers worldwide. The unique ecosystem within these parks fosters competition, innovation, and efficiency, resulting in exceptional value for buyers.

Cost-Effective Production of Aluminum Profiles

Shenzhen's mechanical parks advantage from economies of scale and optimized supply chains, empowering producers to deliver aluminum profiles at profoundly competitive costs. The near nearness of crude fabric providers, expulsion offices, machining workshops, and wrapping up plants diminishes transportation time and coordinations costs. Robotized generation lines and proficient workflows assist lower labor and operational costs.

Producers as often as possible share assets such as testing centers, tooling administrations, and upkeep back, contributing to extra fetched reserve funds. For OEM clients, these preferences interpret into moved forward benefit and the capacity to offer more competitive estimating in their claim markets. Indeed with high-quality guidelines, Shenzhen providers reliably provide solid esteem over arrange sizes.

Customization and Flexibility in Aluminum Profile Design

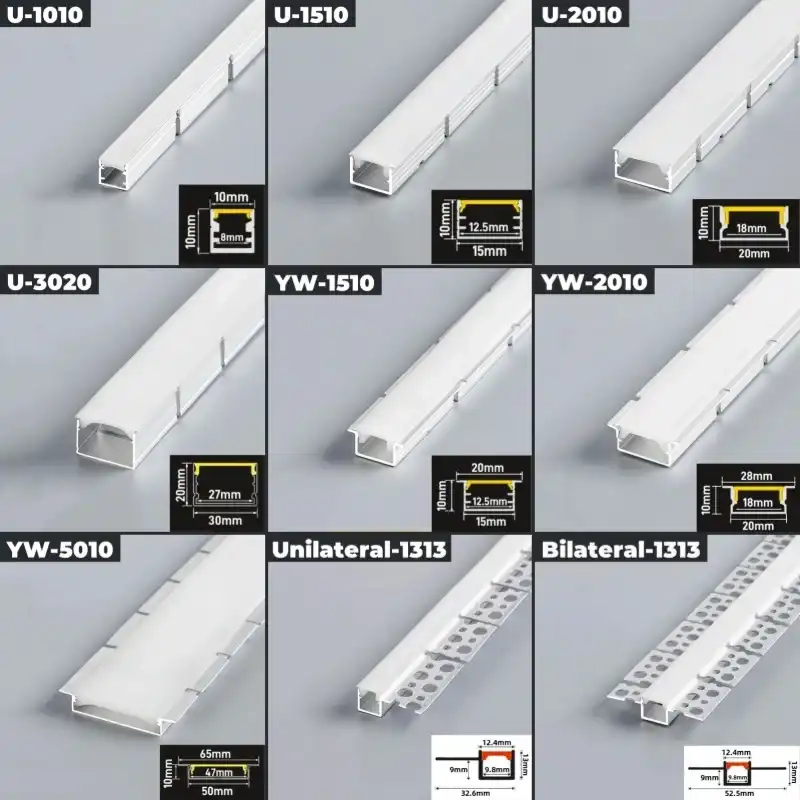

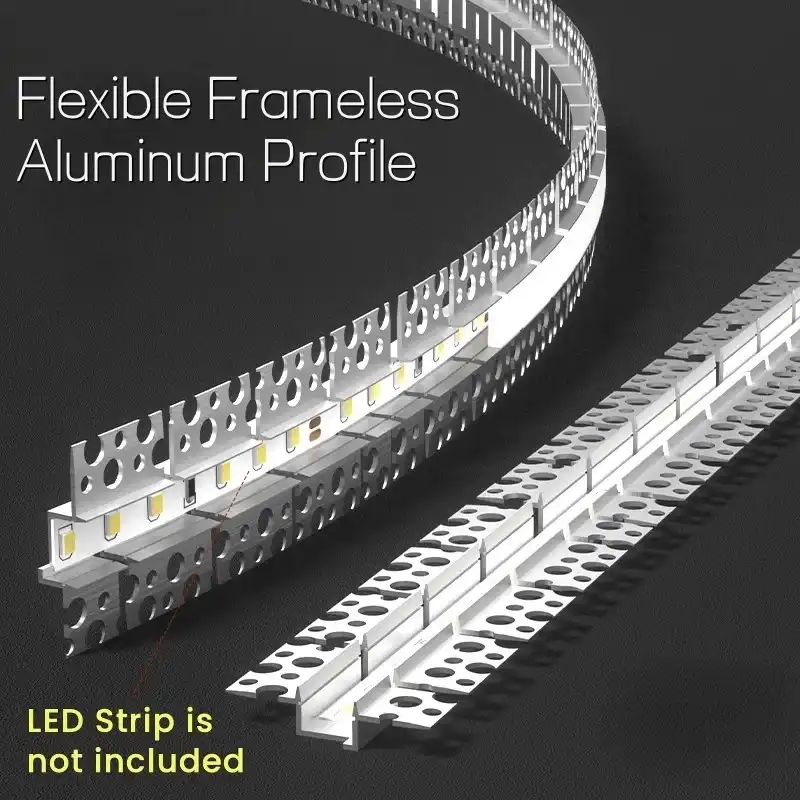

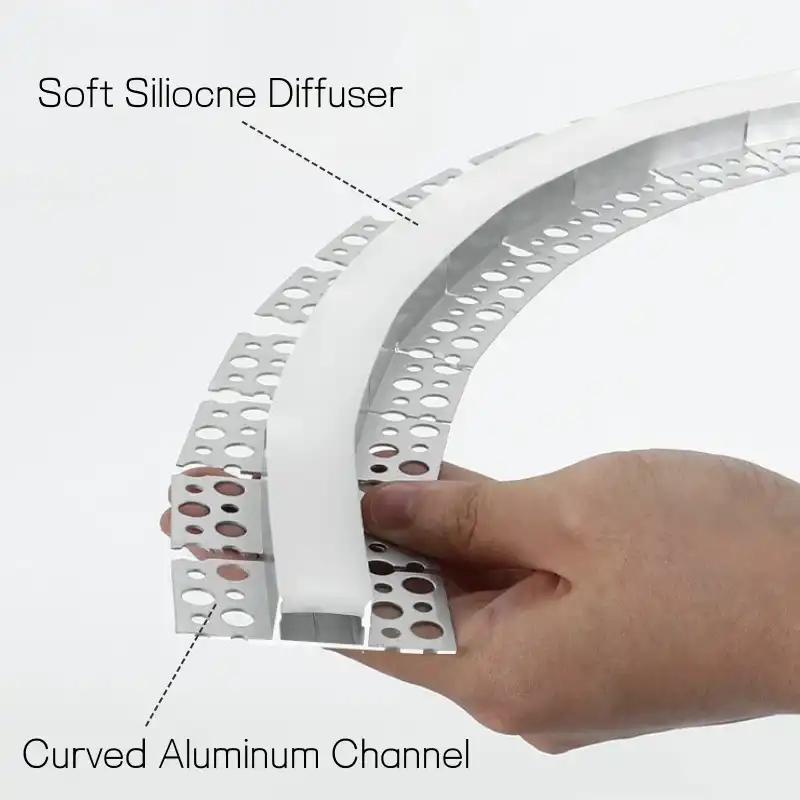

The fabricating capabilities inside Shenzhen's mechanical parks are exceedingly versatile, advertising broad customization alternatives for aluminum profiles. OEM clients can collaborate with producers to design one of a kind shapes, edge medications, and basic highlights custom fitted to particular applications. Customization too expands to anodizing colors, powder-coated wraps up, surfaces, and specialized coatings for erosion resistance or warm execution.

A few producers are able of creating restrictive combination definitions to accomplish wanted mechanical properties. Adaptable generation lines and fast tooling administrations permit for effective moves between models and mass generation. This level of plan adaptability makes Shenzhen a favored choice for businesses looking for inventive, separated, or application-specific aluminum profile solutions.

Rapid Prototyping and Production Scaling

The comprehensive biological system inside Shenzhen's mechanical parks empowers fast prototyping and consistent scaling of aluminum profile generation. Progressed CAD/CAM frameworks, coordinates form workshops, and high-speed expulsion gear permit OEM clients to rapidly approve plan concepts and make real-time alterations. Once models are affirmed, producers can quickly move to full-scale generation without compromising quality or consistency.

The accessibility of different expulsion presses and wrapping up lines inside the same stop guarantees that expanded request can be obliged with negligible delays. This adaptability is especially important for businesses with fluctuating showcase requests or tight extend plans, guaranteeing dependable and spry bolster from concept to mass production.

Quality Control and Certification in Shenzhen's Aluminum Profile Industry

Ensuring the quality and reliability of aluminum profiles is paramount for OEM customers. Shenzhen's industrial parks have implemented rigorous quality control measures and adhere to international standards to meet the exacting requirements of global markets.

Stringent Quality Assurance Processes for Aluminum Profiles

Manufacturers inside Shenzhen's mechanical parks utilize thorough quality confirmation forms to guarantee the unwavering quality of aluminum profiles. Each organize of production—from amalgam confirmation to expulsion, cooling, maturing, machining, and finishing—is closely checked utilizing progressed testing rebellious. Fabric examinations such as XRF and optical emanation spectroscopy confirm combination compositions, whereas facilitate measuring machines (CMMs) guarantee dimensional precision.

Mechanical tests, erosion resistance assessments, and surface attachment checks are routinely performed. Numerous industrial facilities moreover keep up natural test chambers to recreate real-world conditions. These comprehensive quality controls offer assistance producers meet the tall desires of worldwide OEM clients and diminish the hazard of abandons or inconsistencies.

International Certifications and Compliance

Many aluminum profile producers in Shenzhen's mechanical parks hold worldwide certifications that illustrate adherence to worldwide measures. Certifications such as ISO 9001 guarantee vigorous quality administration frameworks, ISO 14001 affirms natural obligation, and IATF 16949 highlights capability for automotive-grade generation. These qualifications grant OEM clients certainty in the consistency and unwavering quality of the items they get.

Producers are too recognizable with assembly compliance necessities for markets such as Europe, North America, and Southeast Asia, counting RoHS, REACH, and industry-specific benchmarks. Their involvement empowers consistent participation with clients who require documentation and testing for specialized applications, from hardware to construction.

Traceability and Documentation

Shenzhen's mechanical parks utilize progressed traceability frameworks that permit OEM clients to track each organize of aluminum profile generation. Advanced records connect each clump to point by point fabric certificates, expulsion parameters, warm treatment logs, and quality review reports. These records give straightforwardness and guarantee compliance with administrative or industry-specific prerequisites.

Such traceability is basic for segments like car, aviation, and high-end hardware, where responsibility and consistency are fundamental. The accessibility of comprehensive documentation moreover disentangles reviews, bolsters guarantee claims, and helps in long-term item observing. This fastidious approach strengthens client certainty and reinforces long-term provider partnerships.

Conclusion

Shenzhen's industrial parks have established themselves as premier destinations for OEM aluminum profiles procurement. The combination of advanced manufacturing capabilities, skilled workforce, and commitment to quality has positioned Shenzhen as a global leader in this sector. OEM customers seeking reliable, cost-effective, and innovative aluminum profile solutions would do well to explore the opportunities presented by Shenzhen's thriving industrial ecosystem.

FAQ

What types of aluminum profiles can be sourced from Shenzhen industrial parks?

Shenzhen manufacturers offer a wide range of aluminum profiles, including standard and custom designs for various applications such as construction, automotive, and electronics.

How do Shenzhen industrial parks ensure the quality of aluminum profiles?

Manufacturers in Shenzhen employ stringent quality control measures, including material testing, dimensional inspection, and adherence to international standards and certifications.

Can OEM customers request custom aluminum profile designs?

Yes, many manufacturers in Shenzhen's industrial parks offer customization services, allowing OEM customers to develop bespoke aluminum profile designs tailored to their specific requirements.

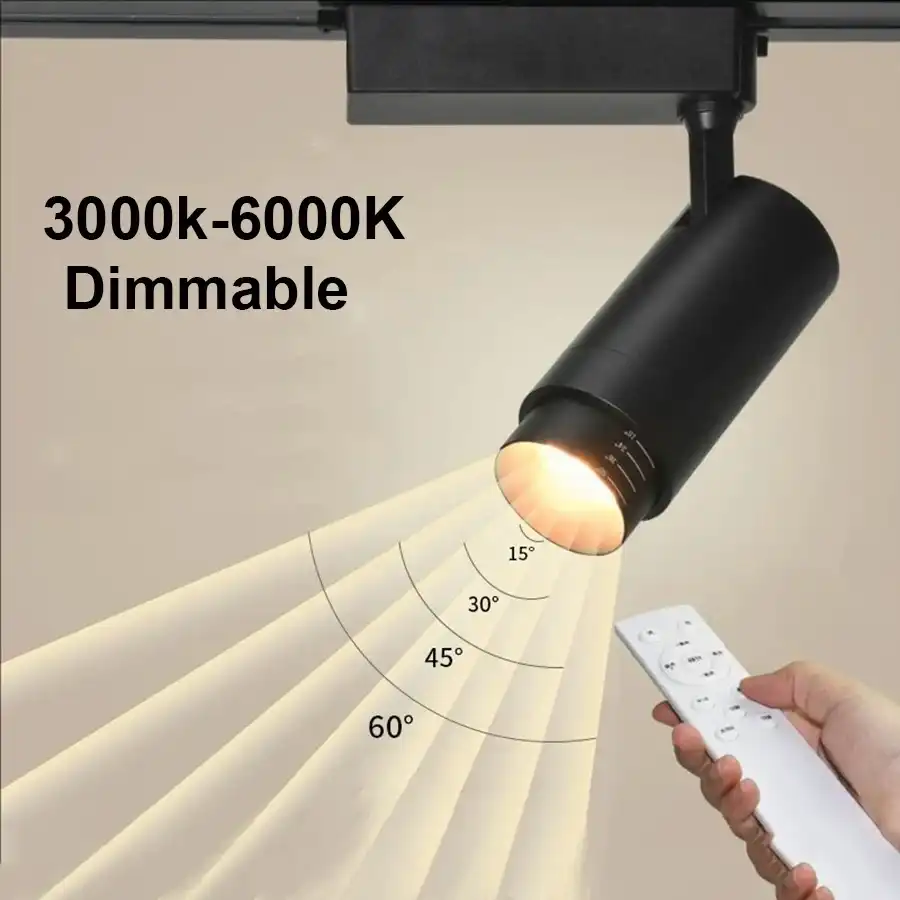

Illuminate Your Space with USKYLED's Premium Aluminum Profile LED Lighting Solutions

USKYLED, a leading manufacturer of high-performance LED lighting solutions, offers an extensive range of aluminum profile-based products. Our cutting-edge designs incorporate advanced LED technology, delivering superior illumination for commercial and residential spaces. From linear lights to architectural luminaires, our custom OEM/ODM solutions cater to diverse lighting needs. Experience the perfect blend of form and function with USKYLED's energy-efficient, sustainable lighting solutions. Transform your projects with our innovative designs – contact us at sales@uskyled.com to explore our aluminum profile LED lighting options.

References

1. Zhang, L., & Wang, H. (2021). "Shenzhen's Industrial Parks: A Model for Sustainable Manufacturing." Journal of Industrial Ecology, 25(3), 567-582.

2. Chen, X., & Li, Y. (2020). "Aluminum Profile Manufacturing in Shenzhen: Innovations and Global Impact." International Journal of Manufacturing Technology and Management, 34(2), 123-140.

3. Liu, J., & Tan, K. (2022). "Quality Control Practices in Shenzhen's Aluminum Extrusion Industry." Total Quality Management & Business Excellence, 33(5-6), 678-695.

4. Wang, R., & Zhou, S. (2019). "The Role of Industrial Parks in Shenzhen's Economic Development: A Case Study of the Aluminum Sector." Urban Studies, 56(4), 789-806.

5. Yang, H., & Wu, X. (2023). "Sustainable Practices in Aluminum Profile Production: Lessons from Shenzhen's Industrial Parks." Journal of Cleaner Production, 375, 134111.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)