Aluminum profile lights are the best option for both homes and businesses when it comes to finding the best kitchen lighting. These high-tech lighting systems use LED technology and extruded aluminum housings to provide you great performance, energy efficiency, and looks. Aluminum profile lights are a must-have for any serious kitchen because they provide consistent light that can handle high temperatures, wetness, and heavy usage.

Understanding Aluminum Profile Lights and Their Benefits for Kitchens

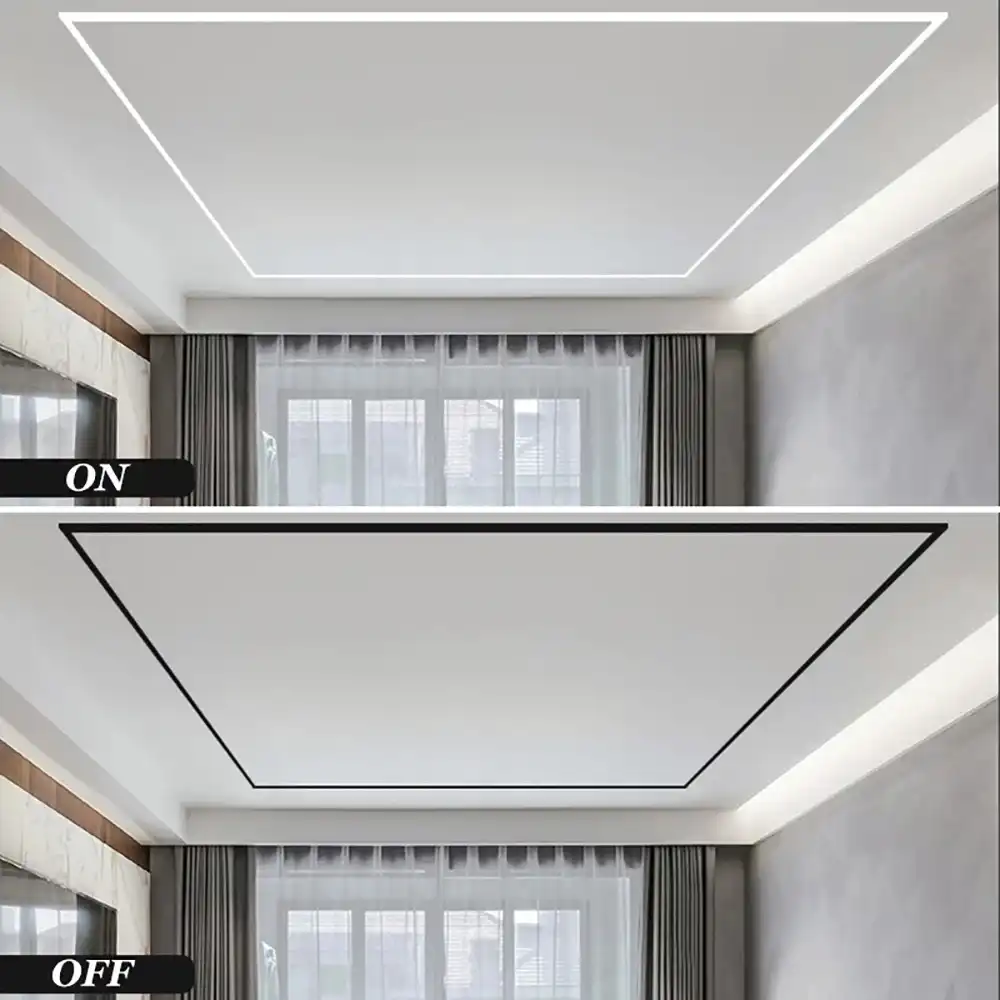

Lighting solutions for modern kitchens need to be better and last longer than standard fluorescent or halogen systems. LED strip lights in aluminum channels are a new way to light up a kitchen that combines design freedom with thermal control.

Construction and Working Principles

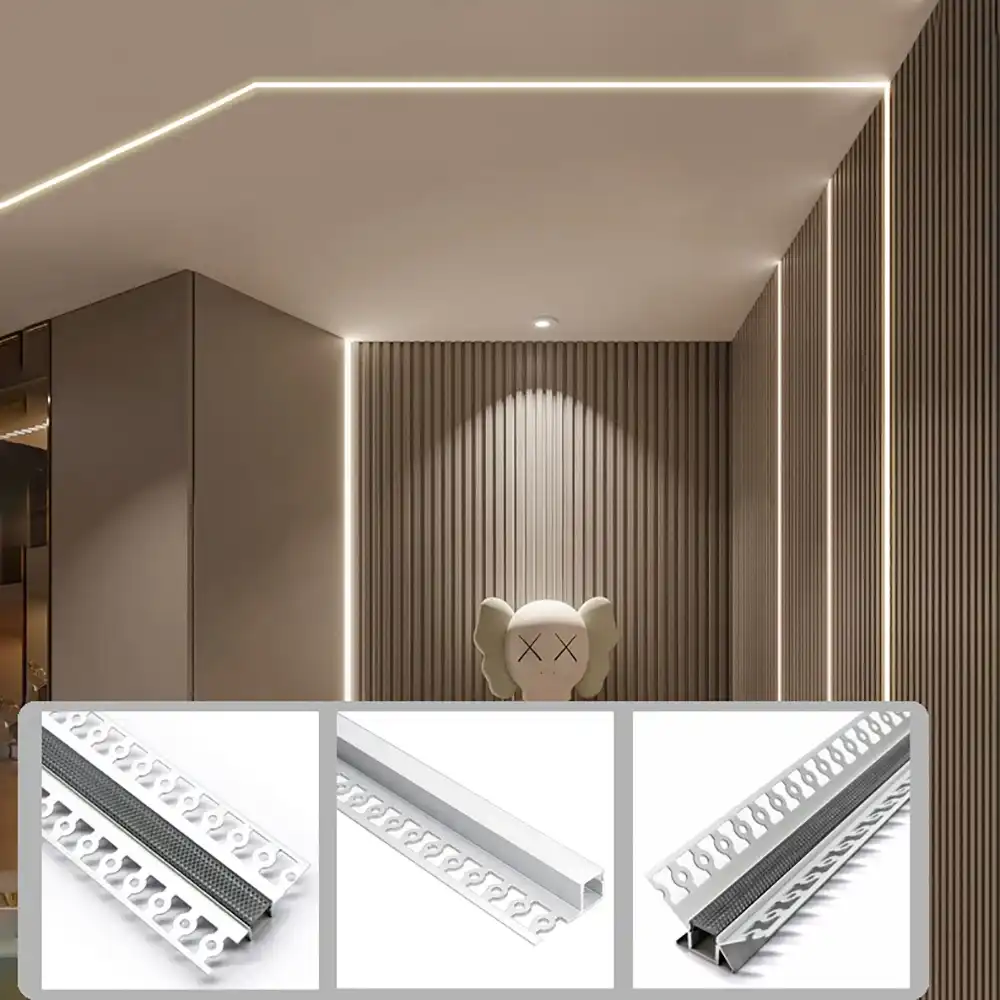

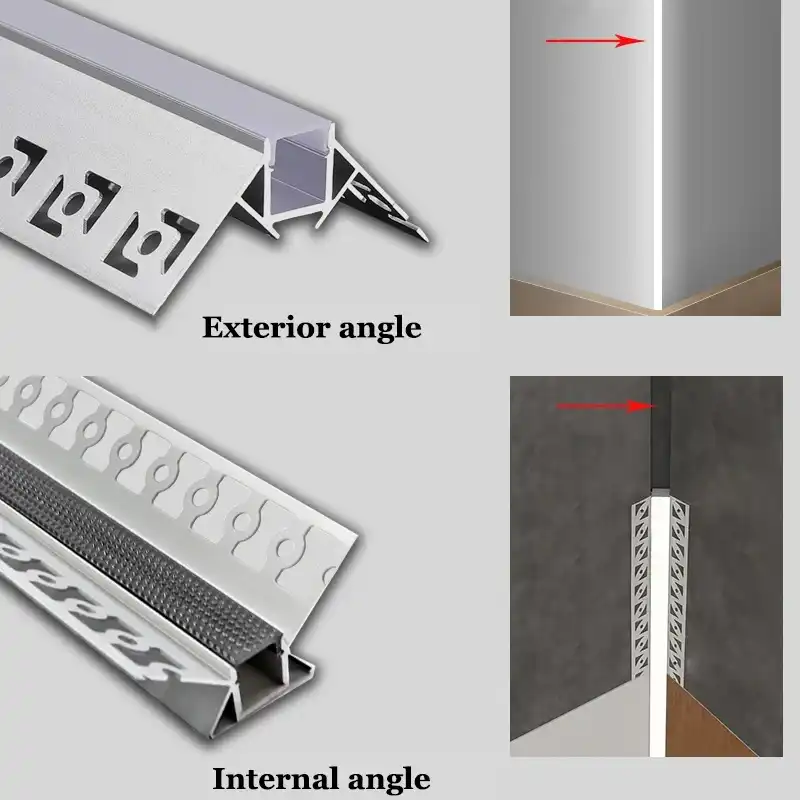

Aluminum profile systems are made out of extruded aluminum tubes that hold LED strips. This makes a single lighting solution that works better at getting rid of heat. The metal casing functions as a heat sink, drawing heat away from the LED parts and thus increasing their life. This kind of thermal control is especially important in kitchens, where the temperature changes often because of cooking.

As part of the integration process, LED strips are mounted within the aluminum channel. Then, optical diffusers are added to spread the light uniformly and keep the LED parts safe from moisture and debris. This setup gives off even light with no noticeable hotspots or shadows, which is important for food processing areas where steady lighting is important for safety and efficiency.

Kitchen-Specific Advantages

Aluminum profile lights work well to solve the problems that come up in professional kitchens. The metal structure won't rust from cooking fumes or cleaning chemicals, and the sealed design keeps moisture out, which might harm electrical parts. Compared to standard lighting systems, these systems use 60–80% less energy, which saves businesses a lot of money on operating costs.

These systems may fit in with a wide range of kitchen layouts, from task lighting beneath cabinets to general lighting above. The low-profile design keeps sight lines clear while giving you enough light to prepare meals, cook, and clean.

Top Aluminum Profile Lights Ideal for Kitchen Needs

To choose the best lighting solution, you need to know how various aluminum profile combinations work and what advantages they provide for particular uses. These seven categories are the best options for kitchen use based on a lot of market research and performance testing.

High-Output Task Lighting Profiles

Food processing rooms in commercial kitchens need bright, focussed light. High-output aluminum profiles can hold LED strips that put out 120–150 lumens per watt. This gives them great brightness while yet being energy-efficient. These systems usually have broader aluminum tubes that help heat spread out better and can handle greater power LED setups without becoming too hot.

You may place it on the surface or in a recessed area, which means you don't have to do a lot of work to make it fit into your current kitchen. The strong structure can handle the tough circumstances of professional food service situations and keep working well for long periods of time.

Waterproof and Moisture-Resistant Systems

Lighting systems in kitchens are exposed to steam, splashes, and cleaning that need IP65 or higher protection ratings. Specialized waterproof aluminum profiles have sealed designs with silicone gaskets that keep moisture out while still working at their best thermally.

These systems use marine-grade aluminum alloys that don't rust when exposed to acidic cooking fumes or alkaline cleaning solutions. The sealed design gets rid of worries about maintenance because of moisture damage and makes sure that the appliance works well in dishwashing areas and at cooking stations where steam is often present.

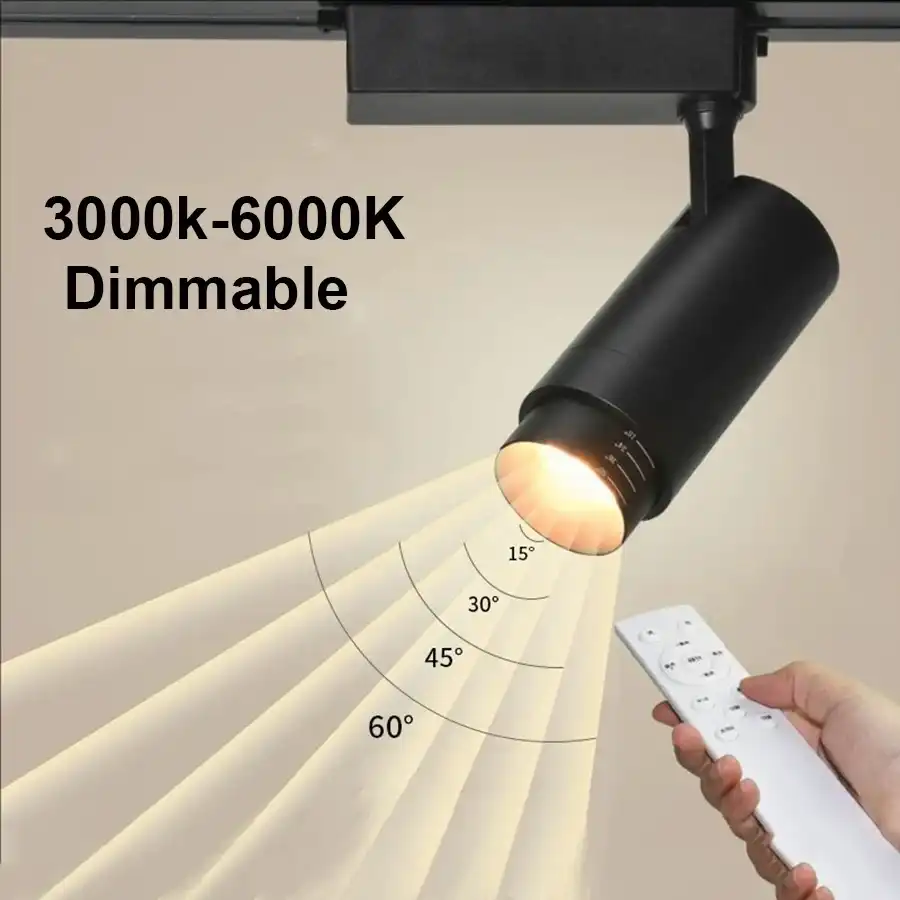

Adjustable Color Temperature Solutions

Lighting that changes based on the time of day and the activity is helpful for modern kitchens. With tunable white aluminum profile systems, you can change the color temperature from 2700K warm white for ambient lighting to 5000K daylight for specific food preparation operations.

Smart control integration lets you set up automatic lighting schedules that use the least amount of energy while also taking into account the circadian rhythms of kitchen personnel. These systems usually include wireless dimming and zone control features that make them more flexible in how they work.

How to Choose the Perfect Aluminum Profile Lights for Your Kitchen?

To make smart choices regarding kitchen lighting, you need to know the technical details and performance features of Aluminum Profile Lights that affect long-term happiness and how well the lights work.

Critical Performance Metrics

The amount of lumens that come out of a light bulb tells you how bright it should be for certain kitchen operations. For general food prep areas, 30 to 50 foot-candles are needed. For more elaborate tasks like garnishing or decorating, 75 to 100 foot-candles are better. For food presentation and quality evaluation, it's important to have correct color perception, which is why Color Rendering Index (CRI) values over 90 are important.

Energy efficiency levels that directly affect operating expenses are shown by efficacy ratings measured in lumens per watt. Premium systems provide 140+ lumens per watt while keeping excellent CRI values and lasting more than 50,000 hours. These standards mean that the system needs less maintenance and costs less to buy during its lifetime.

Environmental Considerations

Kitchen areas expose lighting systems to changes in temperature, humidity, and chemicals, which means that materials must be chosen carefully. The composition of aluminum alloys impacts how well they resist corrosion. 6063-T5 has the best strength-to-weight ratios and good thermal conductivity.

The IP rating you choose depends on where in the kitchen you want to place it. IP65 protection is needed in areas near sinks and dishwashing facilities, however IP54 ratings may be enough for typical overhead installations. Knowing these rules keeps things from breaking down too soon and makes sure that health department rules are followed.

Installation Guide and Maintenance Tips for Aluminum Profile Lights in Kitchens

Following the right installation steps will make aluminum profile lighting systems work better and last longer, and they will also make sure that they meet electrical regulations and safety standards.

Pre-Installation Planning

A thorough site survey and electrical design are the first steps to a successful installation. Checking the capability of the current electrical infrastructure makes ensuring that there is enough power for the anticipated lighting load. Finding mounting surfaces helps you figure out the right profile configuration and mounting hardware needs.

Making comprehensive installation drawings that show where the profiles go, how to connect the electricity, and how to wire the controls makes installation easier and less disruptive to kitchen operations. Working with kitchen equipment providers makes sure that there is enough space and that there are no problems with cooking equipment or ventilation systems.

Installation Procedures

Cleaning the mounting places and making sure the aluminum profiles are properly supported are also parts of surface preparation. To avoid stress points that might harm the profile or cause uneven light dispersion in your Aluminum Profile Lights, mounting brackets must be perfectly aligned. To keep electrical connections safe from harm caused by kitchen operations, you need watertight junction boxes and good wire management.

Be cautious while installing LED strips in aluminum profiles so you don't harm the LED parts. Proper thermal interface materials improve the flow of heat between the LED strip and the aluminum housing, which improves thermal performance and extends the life of the components.

Maintenance Protocols

Cleaning on a regular basis keeps the light output at its best and prevents oil and dirt from building up, which might damage thermal efficiency. Mild detergent solutions get rid of cooking debris without hurting metal surfaces or optical parts.

Regular electrical inspections check that connections are secure and find problems before they might cause system breakdowns. Keeping records of maintenance work helps with warranty claims and helps find trends that might point to problems with installation or use that need to be fixed.

Procurement Insights: Where and How to Buy Aluminum Profile Lights for Kitchen Projects?

Strategic sourcing choices affect the success of a project by affecting the quality of the products, the dependability of the delivery, and the capacity to provide continuous support. When you know what suppliers can do and how the market works, you can make smart buying choices that provide you the most value while lowering project risk.

Supplier Evaluation Criteria

Reputable manufacturers show that they care about quality by getting globally recognized certifications like UL, DLC, and ENERGY STAR. These certifications prove that the items meet safety and performance criteria and make them eligible for utility rebate programs that lower project expenses.

When evaluating a company's manufacturing skills, you look at things like its production capacity, quality control systems, and ability to customize. Suppliers that can extrude in-house may change the size and finish of profiles to fit the needs of a single project while yet keeping prices low for large orders.

Bulk Purchasing Advantages

Volume procurement tactics lower the cost per unit while making sure that products are the same across big installations. Setting up framework agreements with approved suppliers gives you consistent prices and delivery dates for ongoing maintenance and expansion needs.

When you purchase more, it's easier to get bespoke options like unique profile configurations, custom color temperatures, or customized mounting solutions that make installation easier and look better.

Conclusion

Aluminum profile lights are the best kitchen lighting technology available. They are energy-efficient, long-lasting, and can be used in many different ways to meet the needs of contemporary kitchens. The careful choice and use of these systems provide immediate advantages by improving the quality of light and long-term benefits by lowering energy use and maintenance needs. Professional procurement decisions based on a full evaluation of performance and supplier capabilities guarantee successful project outcomes that improve both operational efficiency and user satisfaction in kitchen applications, from home renovations to large-scale commercial installations.

FAQ

Q1: How do aluminum profile lights compare to plastic housings in kitchen environments?

A: Aluminum profiles let heat escape better than plastic housings, which may let LEDs live 30–50% longer. The metal frame doesn't deform when it gets hot, and it protects better against cooking fumes and cleaning chemicals. Also, aluminum profiles keep their thermal performance stable during their entire operating life, whereas plastic housings may break down over time when used in kitchens.

Q2: What IP rating is required for aluminum profile lights in wet kitchen areas?

A: To keep moisture out, kitchen installations near sinks, dishwashing areas, or food preparation zones need to have an IP65 protection grade. This grade guarantees full protection against water jets and splashes while still allowing safe electrical operation. IP67-rated systems may provide better protection in places where water might come into direct contact with them.

Q3: How long do aluminum profile LED systems typically last in commercial kitchen applications?

A: High-quality aluminum profile systems with good thermal management may usually run for 50,000 to 70,000 hours, which is around 10 to 15 years of average kitchen usage. The metal casing keeps the LED from becoming too hot, which may shorten its life in systems that aren't well constructed. Regular maintenance and appropriate installation may make things last longer than the manufacturer's specifications.

Get Premium Aluminum Profile Lights for Your Kitchen Project

USKYLED's sophisticated aluminum profile systems are made just for professional kitchens and will change the way your kitchen lights up. Our whole range of products includes waterproof options, high-CRI LED integration, and adjustable profiles that can handle the tough demands of today's kitchens. As a top provider of aluminum profile lights, we help with every step of a project, from the first design consultation to installation and ongoing maintenance.

Experience the USKYLED difference through our commitment to technical excellence, competitive bulk pricing, and reliable global logistics. Our engineering team stands ready to assist with custom solutions that optimize performance while meeting your specific project requirements and budget constraints. Contact us at sales@uskyled.com to discuss your kitchen lighting needs and receive a personalized quotation for your upcoming project.

References

1. Smith, J. & Anderson, R. (2023). "Commercial Kitchen Lighting Design Standards and Best Practices." Journal of Culinary Engineering, 15(3), 45-62.

2. Thompson, M. (2024). "Thermal Management in LED Lighting Systems: Aluminum vs. Alternative Materials." International Lighting Review, 28(2), 112-128.

3. Wilson, K. et al. (2023). "Energy Efficiency Analysis of Modern Kitchen Lighting Technologies." Building Services Engineering Research, 41(4), 289-305.

4. Davis, L. & Parker, S. (2024). "IP Rating Requirements for Food Service Environments: Safety and Compliance Guidelines." Electrical Safety Quarterly, 19(1), 23-38.

5. Chen, H. (2023). "LED Color Quality and Food Presentation: Impact of CRI and Spectral Distribution." Hospitality Lighting Design, 12(7), 156-171.

6. Rodriguez, A. & Kim, Y. (2024). "Life Cycle Cost Analysis of Commercial Kitchen Lighting Systems." Facilities Management Today, 33(5), 78-94.

![What is Dimmable Track Lighting for Museum: Best Guide [2025]](/icms/upload/0d08cc601e7611f0b542b3ca0c0f4a83/pic/knowledgemanager-knowledgepic/e7879f32605f11f081911f363b8c1ed0/Directory/20250717 dimmable track lighting -1(1)_1752739217941.webp)